مسكن

>

bowl mill coal pulverizer gif

مسكن

>

bowl mill coal pulverizer gif

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

bowl mill coal pulverizer gif

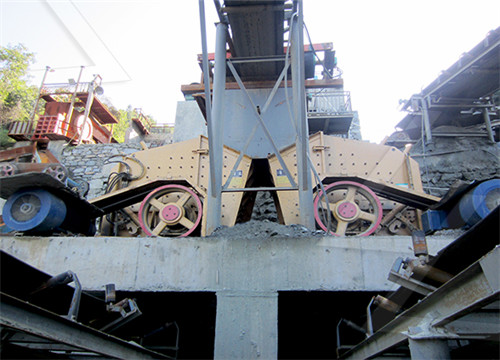

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

IntroductionTypes of Coal PulveriserOperation of Bowl Mill PulveriserOperation of Ball Mill PulveriserThe main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling systemthrough coal feeder into a pre-determined size in order to increase the surface area of the coal. If the coal is not pulverised, the coal might not burn completely, thus resulting in wastage of fuel. 在coalhandlingplants上

Bowl Mill (Pulverizer) in Thermal Power Plant

2024/11/20 The Bowl Mill, also known as a pulverizer, incorporates the best features of various coal grinding systems, making it an efficient and reliable choice for. ... The Bowl Mill is

获取价格

Mill, Raymond, Bowl, Mdl 573, 26,000# coal/hr #C738790

Raymond bowl mill, Model 573, coal pulverizer. Last used to fire rotary kiln in cement plant rated at 26,500 pounds per hour on coal. ... Mill, Raymond, Bowl, Mdl 573, 26,000# coal/hr #C738790. ... Note: We accept document, image

获取价格

Coal mill pulverizer in thermal power plants PPT - SlideShare

sbm bowl mill coal pulverizer animation.md

Contribute to crush2022/mill development by creating an account on GitHub.

获取价格

Coal Pulverizer – Power Plant Pall Corporation

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the

获取价格

HP Bowl type mills-power plant equipment

HP type bowl pulverizer has 9 series and 30 specifications, the model is HP583-HP1303, which can be matched with 50 ~ 1000MW and above thermal power units. 2. Main technical parameters. The basic parameters of HP bowl mill with

获取价格

533 Raymond Bowl Mill - Wabash Power

4 (Four) Reconditioned #533 C-E Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 20,000#/hr. on 55 grindibility coal pulverized to 70% minus 200 mesh. Mills are capable of grinding down to 90% minus 200 mesh as well as

获取价格

Presentation ON Pulveriser: Presented by Debasis

The document discusses pulverizers, which are equipment used to pulverize coal into a fine powder for steam generation in boilers. It describes the types of pulverizers like ball tube mills, bowl mills, and impact mills. It explains the

获取价格

Coal mill pulverizer in thermal power plants PPT

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50,

获取价格

US7673827B2 - Bowl mill for a coal pulverizer with an air mill for ...

A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowl-like grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ). The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 ...

获取价格

573 Raymond Bowl Mill - Wabash Power

(Three) Reconditioned Center Feed #573 C-E Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 26,500#/hr. on 55 grindibility coal pulverized to 70% minus 200 mesh. Mills are capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove coal but at a lower rating. Units are equipped with all internal related ...

获取价格

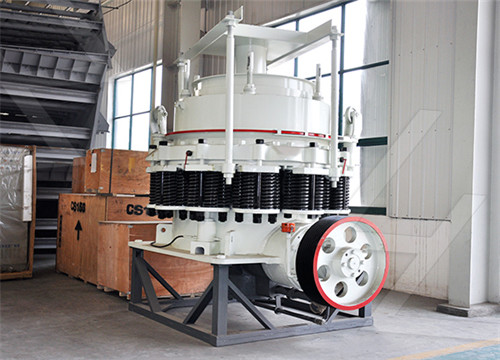

Raymond Bowl Mill designed and built for flexibility - Qlar

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (<5%R75μ) with a

获取价格

Bowl mill in thermal power plant PPT - SlideShare

2020/4/1 5. type of mill xrp 1003 mill base capacity(t/hr) * 67 motor speed (rpm) 985 total weight of mill (t) (including motor) 130 type of load moderate shock load rotating weight of mill(t) 22.88 spring rate(kg/cm) 5359 spring pre-load(kg) 9500 mill outlet temperature range 65ºc -90ºc air flow 102 t/hr fineness 70% through 200 mesh

获取价格

Home Kappati Bowl Mills

Pulverizers Assemblies. Pulverizer Spares. Coal Nozzle. Castings. Forgings. Rings, Girth Gears and Flanges. Shafts. Manufacturing Process. Engineering And Servicing. ... a qualitative economical alternative to different Original Equipment Manufacturers around the world in the field of Bowl Mills, Industrial Turbines, Gas Turbines, and And ...

获取价格

Pulverizer Maintenance Guide, Volume 1 Raymond Bowl

Pulverizer mill Exhauster Coal feeder Maintenance Reliability Troubleshooting 15376899. EPRI Licensed Material vii ... This guide covers all of the maintenance issues for the Raymond Bowl pulverizer mill designs. It is intended to improve the maintenance practices and reliability of the equipment. 15376899. 15376899.

获取价格

Presentation ON Pulveriser: Presented by Debasis Mahapatra PDF Mill

The document discusses pulverizers, which are equipment used to pulverize coal into a fine powder for steam generation in boilers. It describes the types of pulverizers like ball tube mills, bowl mills, and impact mills. It explains the advantages of pulverized coal firing and discusses components like raw coal feeding, drying, grinding, classifying, and transporting. Key points

获取价格

BW ROLL WHEEL PULVERIZERS - Babcock Wilcox

The BW Roll Wheel pulverizer design results in superior mill performance and cost benefits. 3 ... Reliable coal pulverizer performance is one element that is essential for sustained responsive power plant operation. More than the name has changed Since introducing the roll wheel pulverizer, Babcock Wilcox (BW) has made substantial and extensive

获取价格

Raymond® Bowl Mill - Coperion

The Raymond® Bowl Mill is considered the finest vertical rollermill available for pulverizing coal. Each bowl mill system is designed to achieve thebest solution forthe processing application. The mill, feeder, classifier, fan, cyclone,dust collector and other system components are selected to meet the requirementsand characteristics of the material processed.

获取价格

“Blueprint” Your Pulverizer for Improved Performance

the pulverizer throats and matching them for compatibility with the coal pipes and burner nozzle sizes is essential for the best furnace performance. Furthermore, remember that there will be minor vari-ation in mill capacity, fuel quality, and mill inlet airflow rates that must be considered when sizing the pulverizer throat flow area.

获取价格

How Vertical Grinding Mills Work (Coal Pulverizer Example)

Want to continue learning about engineering with videos like this one? Then visit:https://courses.savree/ Want to teach/instruct with the 3D models shown...

获取价格

Industrial Bowl Mills - Bowl Mill Pulverizer for Sale - Wabash

Wabash is a supplier of refurbished Raymond bowl mills and hammer mills. We have a huge inventory of refurbished mills ready to ship. ... Back to Pulverizers Mills. When it comes to coal pulverization, a bowl mill is the most preferred and utilized mill. The capacity in pounds per hour of the mill is calculated on the assumption that the coal ...

获取价格

Pulverizer Spares - Kappati Bowl Mills

Pulverizers Assemblies. Pulverizer Spares. Coal Nozzle. Castings. Forgings. Rings, Girth Gears and Flanges. ... Pulverizer Spares. RP, RPS, HP Mills SPARES LIST FOR RP, RPS, HP Mills 603 To 1203 SIZE O E M PART NO. FROM EACH TYPE OF MILL WILL BE DIFFERENT. PULVERIZER SPARES. AIR CYLINDERSAIR SEAL HSG ASSLY ... BOWL ( GRINDING

获取价格

“Blueprint” Your Pulverizer for Improved Performance

the pulverizer throats and matching them for compatibility with the coal pipes and burner nozzle sizes is essential for the best furnace performance. Furthermore, remember that there will be minor vari-ation in mill capacity, fuel quality, and mill inlet airflow rates that must be considered when sizing the pulverizer throat flow area.

获取价格

How Vertical Grinding Mills Work (Coal Pulverizer Example)

观看视频14:392019/6/14 Want to continue learning about engineering with videos like this one? Then visit:https://courses.savree/ Want to teach/instruct with the 3D models shown...

获取价格

Industrial Bowl Mills - Bowl Mill Pulverizer for Sale - Wabash

Wabash is a supplier of refurbished Raymond bowl mills and hammer mills. We have a huge inventory of refurbished mills ready to ship. ... Back to Pulverizers Mills. When it comes to coal pulverization, a bowl mill is the most preferred and utilized mill. The capacity in pounds per hour of the mill is calculated on the assumption that the coal ...

获取价格

Pulverizer Spares - Kappati Bowl Mills

Pulverizers Assemblies. Pulverizer Spares. Coal Nozzle. Castings. Forgings. Rings, Girth Gears and Flanges. ... Pulverizer Spares. RP, RPS, HP Mills SPARES LIST FOR RP, RPS, HP Mills 603 To 1203 SIZE O E M PART NO. FROM EACH TYPE OF MILL WILL BE DIFFERENT. PULVERIZER SPARES. AIR CYLINDERSAIR SEAL HSG ASSLY ... BOWL ( GRINDING

获取价格

Pulverizer Plant OM Aspects - eecpowerindia

Pulverizer Plant OM Aspects Dr. T K Ray NTPC Limited E-mail: rayt3@asme ... Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Model no. Base capacity(T/Hr) ... Maximum mill Capacity vs coal moisture at coal HGI 100-110 and PF Fineness of 70 % passing through 200 Mesh 35.00 36.00 37.00

获取价格

Home - GPL

We provide trusted service in fabrication, Manufacturing, Engineering and Assembly of Coal Pulverizing Mills used in Thermal Power Projects. Kappati is a market leader in the field of manufacture of Assemblies , OM replacement parts, Engineering, and servicing for Coal Pulverizers RP, RPS, HP Mills form 603 to 1203 size used in 60 MW to 800 MW Power

获取价格

Boiler Mill and Coal Pulverizer Performance GE Steam Power

Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

获取价格

US20040227024A1 - Bowl mill for a coal pulverizer with an air mill

A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowl-like grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ). The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 ...

获取价格

World-Proven Coal Pulverizer Technology Debuts in the U.S.

spring-loaded, MB type, vertical spindle mills, each gravimetric belt feeder, seal air fan, 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dual-fuel burners. When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffir.

获取价格

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl mill.Other grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring mill.

获取价格

BW Parts, Services and Programs for CE-Type

Engineered pulverizer parts and upgrades are designed to deliver performance and reliability which provide enhanced operation and value to your plant’s capital investments, regardless of original equipment manufacturer (OEM). BW supports pulverizers/mills manufactured by CE and others, including: • CE/Raymond deep bowl mills

获取价格

sbm bowl mill coal pulverizer animation.md

Animation Of Coal Pulverizer Bowl Mill Coal Pulverizer Gif Laurastownshiptours.Co.Za How a coal pulverizer works coal grinding process 3d animation.here's a 3d animation of how a coal grinding system works.williams crusher has the most advanced direct fired coal and. INTRODUCTION TO BOWL MILLS INTRODUCTION TO BOWL MILLS Coal is the one of the ...

获取价格

Bowl Mill Pulverizer - YouTube

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coa...

获取价格

classifications and working of mills in a power plant PPT

2020/6/29 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill. If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube mill.

获取价格