مسكن

>

heat recovery metallurgical process slag

مسكن

>

heat recovery metallurgical process slag

منتج

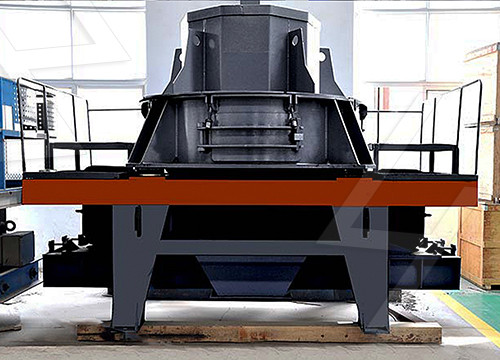

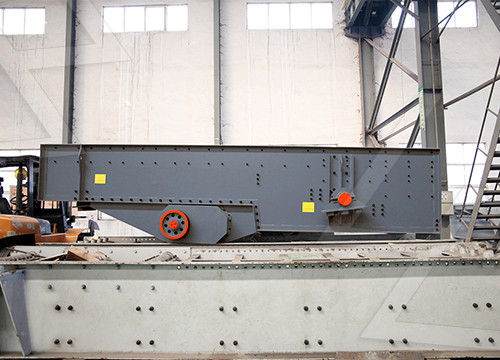

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

heat recovery metallurgical process slag

Granulation and Heat Recovery from Metallurgical Slags

Heat Recovery from Metallurgical Slags • Operating cost 4.80 A$/t slag Recovery of waste

获取价格

Energy recovery from high temperature slags - ScienceDirect

2011/9/1 Metallurgical slags are conventionally divided into ferrous and non–ferrous,

获取价格

(PDF) Metallurgical Processing Strategies for Metals

2019/6/18 The Cr present in stainless steel slag, charg e chrome slag and vanadium slag usu- ally exists as Cr 2 O 3 . However , there is a possibility that it is oxidized to hazardous

获取价格

Process Concept for the Dry Recovery of Thermal

2021/6/24 Slags are valuable by-products of iron- and steelmaking processes. Their efficient reutilization and the recuperation of their thermal

获取价格

(PDF) Heat Recovery from High Temperature Slags: A

2015/3/12 Indeed, a two-step heat recovery process has been forecasted by Barati et al. [8] based on operational process es ; moreover, based on the inherent crystallization properties of slags [28,32], the ...

获取价格

Development of waste heat recovery technology from steel slag

In terms of the waste heat recovery and utilization of steel slag, there are no applica-tion

获取价格

A review of waste heat recovery technologies towards molten slag

2013/12/1 High-temperature waste heat from the iron and steel industry, as shown in

获取价格

Process Concept for the Dry Recovery of Thermal Energy of

5 mm. In this process step, the slag heat is not recovered. In a consecutive second step, the

获取价格

Three-Stage Method Energy–Mass Coupling High-Efficiency

2021/6/14 High-temperature molten steel slag is a large amount of industrial solid waste

获取价格

Granulation and Heat Recovery from Metallurgical Slags

2019/12/9 Metallurgical slags are produced at a massive rate of over 750 Mt/year, and carry a thermal energy equivalent to 40 Mt/year of coal. The potential mineral and thermal energy values of slags are in the order of $22 b and $3–6 b per year. Such attractive figures, together with tightening legislation on disposal of slag and the carbon footprint associated with the loss

获取价格

Granulation and Heat Recovery from Metallurgical Slags

2019/12/9 Waste heat recovery from high-temperature slag is the latest potential way to significantly reduce energy consumption and carbon dioxide emissions in the iron and steel industry [6, 7] and can ...

获取价格

Energy recovery from high temperature slags - ScienceDirect

2011/9/1 Metallurgical slags are conventionally divided into ferrous and non–ferrous, based on the metal produced in each process. The typical chemical composition and generation rate of various slags for the major metal manufacturing processes are provided in Table 1, Table 2.As seen, the relative amount of slag produced per ton of iron/steel is lower than the non-ferrous

获取价格

Comprehensive utilisation of blast furnace slag - Taylor Francis

2023/7/21 Introduction. China is the world's largest steel producer, with the China Iron and Steel Association estimating that the country's crude steel production in 2022 will be 935 million tonnes [Citation 1].Steel slag mainly refers to the blast furnace slag and converter slag produced in the process of iron making and steel making, and with the increase of steel production, the

获取价格

Experimental investigation on molten slag granulation for waste heat

2016/6/25 Various slags, for example, blast furnace slag, converter slag, ferroalloy slag and copper slag, are produced as by-products in metallurgical processes. As we know anything so far that a majority of metallurgical slags are treated by water quenching, and the waste energy potential in the high temperature range (1250–1650 °C) have limited ...

获取价格

Experimental investigation on granulation characteristics and

2021/2/5 Molten blast furnace slag (BFS) is the main by-product of iron making process with the 1450–1550 °C discharge temperature [1], which contains large amounts of physical sensible heat and belongs to high-quality waste heat resource [2].Each ton of molten slag contains 1260–1880 kJ thermal energy which is equivalent to 60 kg standard coal [3], [4].

获取价格

Granulation and Heat Recovery from Metallurgical Slags

2022/12/31 The results of the present study show that, in the centrifugal granulation process of blast furnace slag using a spinning cup operated in the ligament disintegration mode, the breakup of a single molten slag ligament is very similar to that of a single water or liquid paraffin ligament, and both approximately follow the Rayleigh Disintegration ...

获取价格

Development of a heat recovery system from steelmaking

absorption, Heat recovery, Steelmaking slag . Abstract . We will introduce the recent development of a ew slag heat recovery system, which consists n of a roll-type continuous slag solidification process and a slag heat recovery process. This work is conducted as one of the COURSE50 national projects in Japan. In this process, the molten slag

获取价格

A review of waste heat recovery technologies towards molten slag

2013/12/1 High-temperature waste heat from the iron and steel industry, as shown in Fig. 1, are mainly stored in products, molten slag and waste gas [2].Molten slag, as a kind of by-product during the steelmaking process, is exhausted in extremely high temperature and thus, it carries a great deal of high-grade heat accounting for 10% of waste energy in steel industry

获取价格

Heat Recovery from High Temperature Slags: A Review of

2015/3/12 Waste heat recovery from high temperature slags represents the latest potential way to remarkably reduce the energy consumption and CO2 emissions of the steel industry. The molten slags, in the temperature range of 1723–1923 K, carry large amounts of high quality energy. However, the heat recovery from slags faces several fundamental challenges,

获取价格

Dry solidification with heat recovery of ferrous slag

2015/6/1 The research team intends to identify the optimum operating conditions of a dry granulation process with heat recovery, and to determine the process boundary conditions that would apply at a full-sized industrial pilot plant. ... Solidification of large quantities of slag, independent of the metallurgical process (BF, BOF, EAF, ladle furnace ...

获取价格

Multi-Step Recycling of BF Slag Heat via Biomass for CO 2

2022/1/25 The torrefaction process is linked with slag heat recovery and via the BASE method with enhanced blast furnace operation. Such a combination reduces CO2 emissions significantly in ironmaking processes. ... Barati, M.; Jahanshahi, S. Granulation and Heat Recovery from Metallurgical Slags. J. Sustain. Metall. 2020, 6, 191–206. [Google Scholar]

获取价格

Future trend of terminal energy conservation in steelmaking plant ...

2022/1/15 Integration consideration of end-point reproductions like molten slag waste heat high-efficiently recovery and resourceful disposal has a significant influence on establishing more economical and environmental wastes circular network system, due to 0.75billiontonne metallurgical slag with nearly 1500 °C is produced annually, corresponding to 40milliontonne

获取价格

Experimental investigation on molten slag granulation for waste heat

2016/6/25 So, more and more researchers begin to develop dry granulation and waste heat recovery system for metallurgical slag. In the work of Xie, the molten slag was tapped onto a water-cooled rotating copper disc, and the solid particles were discharged into an enclosed moving bed. ... New process for dry granulation and heat recovery from molten ...

获取价格

Dry solidification with heat recovery of ferrous slag

2015/6/1 The research team intends to identify the optimum operating conditions of a dry granulation process with heat recovery, and to determine the process boundary conditions that would apply at a full-sized industrial pilot plant. ... Solidification of large quantities of slag, independent of the metallurgical process (BF, BOF, EAF, ladle furnace ...

获取价格

Multi-Step Recycling of BF Slag Heat via Biomass for

2022/1/25 The torrefaction process is linked with slag heat recovery and via the BASE method with enhanced blast furnace operation. Such a combination reduces CO2 emissions significantly in ironmaking processes. ... Barati, M.;

获取价格

Future trend of terminal energy conservation in steelmaking plant ...

2022/1/15 Integration consideration of end-point reproductions like molten slag waste heat high-efficiently recovery and resourceful disposal has a significant influence on establishing more economical and environmental wastes circular network system, due to 0.75billiontonne metallurgical slag with nearly 1500 °C is produced annually, corresponding to 40milliontonne

获取价格

Experimental investigation on molten slag granulation for waste heat

2016/6/25 So, more and more researchers begin to develop dry granulation and waste heat recovery system for metallurgical slag. In the work of Xie, the molten slag was tapped onto a water-cooled rotating copper disc, and the solid particles were discharged into an enclosed moving bed. ... New process for dry granulation and heat recovery from molten ...

获取价格

Development of waste heat recovery technology from steel slag

2023/5/4 Therefore, the efficient recovery and utilization of sensible heat of steel slag has always been the focus of attention of the metallurgical field all over the world.

获取价格

Comprehensive utilisation of blast furnace slag - Taylor

ulation process can be divided into physical recovery method and chemical recovery method. 1.2.1 Physical recovery method The physical recovery method mainly absorbs slag heat energy through water, molten salt and other media, and achieves the effect of heat recovery by using medium heat energy conversion. The physical recovery method

获取价格

Innovative Process for Strategic Metal Recovery from Electric Arc ...

2024/7/22 A clean metallurgical process for separation and recovery of vanadium and chromium from V-Cr-bearing reducing slag. Hydrometallurgy 2018, 181, 1–6. [Google Scholar] Bensamdi, S.; Seron, A.; Pereira, F. Nour-eddine Menad, Recovery of Valuable Metals from EAF Slag by Microwave Assisted Leaching.

获取价格

Disposal of High-Temperature Slags: A Review of Integration of Heat ...

2016/5/4 Through the metallurgical process, the liquid slags were first produced and then supplied into the cup. The cup with liquid slags was then rotated with the set rotating speed, and meanwhile, the compressed air was ejected into the molten slags to improve the granulation process. ... For example, for the slag heat recovery using gasification ...

获取价格

Hot stage processing of metallurgical slags - Academia

In this paper, the slag granulation and heat recovery options are reviewed and given a critical evaluation, aiming to provide a basis for future directions in slag handling. ... A multitude of laboratory and industrial studies have been performed to optimise the chromium recovery inside the metallurgical process (McCoy and Langenberg, 1964 ...

获取价格

High Temperature Rheological Characteristics of Iron and Steel

2020/11/18 In iron making process, the metallurgical . proper es of blast furnace slags are determined largely by . ... process of slag waste heat recovery. The sensible heat of the .

获取价格

Breaking boundaries in slag waste heat recovery: Review and

2024/11/1 Waste heat recovery posed a great challenge for energy saving and consumption reduction in the integrated process flow of ISI. Although the cascade utilization principle of waste heat was widely implemented, there was still a certain lifting space in waste heat recovery, especially for China’s ISI was only 30∼50 % (Zhang et al., 2023a).

获取价格

Experimental investigation and modeling of cooling processes of

2014/11/1 Cai et al. [7] have estimated that the waste-heat recovery rate of metallurgical slags is less than 2% in China. Furthermore, Barati [8] discussed the energy intensity and the CO 2 emission in metallurgical industry and Milford et al. [9] ... and the variation of the slag properties during the cooling process can be therefore figured out. CCT ...

获取价格

Heat recovery from metallurgical molten slag - Google Patents

molten slag heat recovery metallurgical molten metallurgical heat transfer Prior art date 1976-03-24 ... Process for utilizing waste heat from cinder cake US379412A (en) * 1888-03-13: Slag-furnace : US760172A (en) * 1902-02-20: 1904-05-17: Garretson Furnace Company: Slag-furnace. ...

获取价格

The positive contributions of steel slag in reducing carbon dioxide ...

2024/10/15 Steel slag is a by-product generated during the steelmaking process, constituting 15 to 20 % of crude steel production [3].Steel slag possesses significant sensible heat, carbon sequestration potential, and resource utilization capacity, all of which are crucial for reducing CO 2 emissions in the steel industry. Given its high heat content in the molten state,

获取价格