مسكن

>

fluorite ore gold magnetic separator

مسكن

>

fluorite ore gold magnetic separator

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

fluorite ore gold magnetic separator

Fluorite Processing Equipment, Process Flow, Cases

2019/8/23 This process can effectively improve the fluorite efficiency. Magnetic separator picks out the magnetic substances from clean classified fluorite ore, and then adds the corresponding flotation agent for flotation

获取价格

Ultimate Guide for Magnetic Separation Method - Mining-pedia

Iron OreNon-Ferrous and Rare Metal MineralsWeighted MaterialNon-Metallic MineralsRaw Ore PretreatmentStrong Magnetic MineralsWeak Magnetic MineralsNon-Magnetic MineralsAccording to Bearing MediaAccording to The Magnetic Field StrengthMagnetic separation is the main beneficiation method for iron ore processing. After the beneficiation of iron ore, the grade is improved, and the content of silica and harmful impurities is reduced, which is beneficial to the smelting process. We have an article about 5 iron ore beneficiation process, click the link to check it.

Mineral Separation Equipment Flotation, Magnetic Separator

Types of Mining Magnetic Separators - Mineral

6 之 Permanent Drum Magnetic Separator. Permanent drum magnetic separator can dry and wet magnetic separation. wet drum magnetic separator feeding materials from the bottom, but dry drum magnetic separator feeding

获取价格

CTB permanent magnetic drum separator - Jinpeng

Jiangxi 1000t/d fluorite ores processing project; Shandong 2000t/d gold project; ... When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the

获取价格

Popular Beneficiation Methods For Extracting Gold From Minerals

6 之 1. Extracting Gold By Gravity separation. Gold usually exists in the form of monomeric natural gold, which has a large density difference with gangue, so gravity separation is the most important, effective and economical method for separating placer gold/ rock gold.It mainly uses the density difference between gold and associated gangue to create separation conditions,

获取价格

Magnetic Separator Basic Introduction How To Choose

2024/3/5 A magnetic separator is a device that uses a magnetic field to separate ferrous objects from nonferrous objects. It is commonly used in ore extraction, waste treatment, food processing and other industries. Following we will introduce it to you and discuss how to choose it. How Does The Magnetic Separator Work? Magnetic separators typically consist of a rotating

获取价格

wet drum magnetic separator - JXSC Machinery

Wet drum magnetic separator is a highly versatile magnetic separation equipment that separates and purifies various magnetic materials.It is mainly capable of effectively separating and recycling magnetic materials from slurry or wet materials. Wet drum magnetic separators are widely used in separating strong magnetic minerals, and can usually be easily integrated into existing mineral ...

获取价格

Mineral Jig Separator Jig Concentrator - JXSC Machinery

Jig separator (jig concentrator, jig machine, mineral jig, mining jig) is a mining gravity separation equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated. This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals. Jig separator are widely used in various heavy ...

获取价格

Research On Copper-molybdenum Ore Flotation Separation

6 之 Most copper-molybdenum ores adopt the mixed flotation-copper-molybdenum separation process, because molybdenite and chalcopyrite have similar floatability and serious concomitant, and this process has lower cost and simpler process. In general, the mixed collectors of flotation machine use xanthate (butyl xanthate), auxiliary collector hydrocarbon oil

获取价格

Master the Art of Extracting Scheelite and Fluorite Ore Separately

6 之 1. Fluorite ore beneficiation. Fluorite ore beneficiation mainly adopts the flotation method and gravity separation method. The flotation method deals with fine-grained dissemination and low-grade fluorite ore. Flotation is one of the most important beneficiation methods for fluorite ore beneficiation. The only way to get fluorite ore powder.

获取价格

Mineral Separation Equipment Flotation, Magnetic Separator

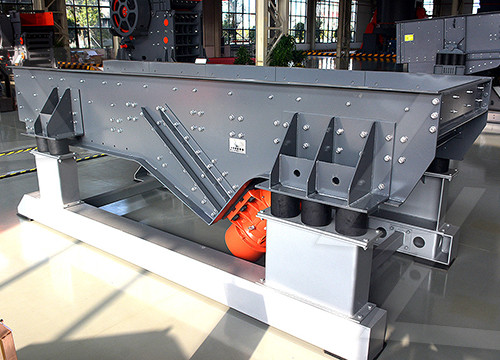

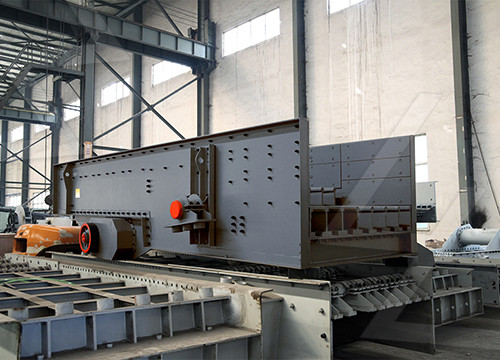

wet drum magnetic separator. Capacity: 0.5-180 t/h Application: Commonly used for wet magnetic separation of pyrite, magnetite, ilmenite, manganese, iron ore and other materials with particle size below 3mm.

获取价格

Three-Disc Magnetic Separator - JXSC Machinery

The three-disc magnetic separator is suitable for precisely separating various magnetic mineral mixed ores. It is mainly used to separate fine-grained weakly magnetic materials from non-magnetic materials, such as ilmenite, monazite, tungsten and tin, tantalum-niobium ore, and other dry separation operations. The induction distance between the magnetic disks at all levels and

获取价格

Fluorite Beneficiation Process - JXSC Mineral

Fluorite ore gravity separation is suitable for higher-grade fluorite ore blocks and particle ores with a particle size of 6-20mm. Fluorite ore flotation is suitable when the raw ore has a high mud content, is accompanied by impurity minerals, or when the

获取价格

Basis, Operation Selection of Electromagnetic Slurry Magnetic Separator

2024/11/25 An electromagnetic slurry magnetic separator is a new type of equipment that utilizes a magnetic field to separate magnetic particles in the slurry.With the continuous progress of science and technology, this technology has been widely used in many fields, especially in mining, environmental protection, and waste treatment, and has achieved remarkable results.

获取价格

Improve Mineral Processing Efficiency By Magnetic Separator

6 之 Magnetic separator is the basic tool used by mineral processing plants to separate ferrous and non-ferrous metals from extracted ore, ensuring high-quality final products. Its works by attracting magnetic particles such as iron, steel and nickel, and then using powerful magnets or electromagnets to separate these particles from other materials.

获取价格

Fluorite Processing Equipment, Process Flow, Cases - JXSC

2019/8/23 Magnetic Separator. Wet Drum Magnetic Separator; ... Gold Sluice Mats Washing Machine; X-ray Ore Sorter; ... Summary of Fluorite Ore Flotation Process. Uses. The majority of the United States’ annual consumption of fluorspar is for the production of hydrofluoric acid (HF) and aluminum fluoride (AlF3). ...

获取价格

Fluorite Beneficiation Process - JXSC Mineral

Fluorite ore gravity separation is suitable for higher-grade fluorite ore blocks and particle ores with a particle size of 6-20mm. Fluorite ore flotation is suitable when the raw ore has a high mud content, is accompanied by impurity minerals, or

获取价格

Basis, Operation Selection of Electromagnetic Slurry Magnetic Separator

2024/11/25 An electromagnetic slurry magnetic separator is a new type of equipment that utilizes a magnetic field to separate magnetic particles in the slurry.With the continuous progress of science and technology, this technology has been widely used in many fields, especially in mining, environmental protection, and waste treatment, and has achieved remarkable results.

获取价格

Improve Mineral Processing Efficiency By Magnetic

6 之 Magnetic separator is the basic tool used by mineral processing plants to separate ferrous and non-ferrous metals from extracted ore, ensuring high-quality final products. Its works by attracting magnetic particles such as iron,

获取价格

Fluorite Processing Equipment, Process Flow, Cases - JXSC

2019/8/23 Magnetic Separator. Wet Drum Magnetic Separator; ... Gold Sluice Mats Washing Machine; X-ray Ore Sorter; ... Summary of Fluorite Ore Flotation Process. Uses. The majority of the United States’ annual consumption of fluorspar is for the production of hydrofluoric acid (HF) and aluminum fluoride (AlF3). ...

获取价格

Tailings Processing Plant Equipment - JXSC Machinery

The tailings reprocessing method is suitable for the re-separation of various tailings, including gold, iron, lead-zinc, copper, fluorite, tungsten, phosphorus, graphite, bauxite tailings, etc. Among them, a centrifugal concentrator is usually used to process gold tailings, so that valuable ore can be separated due to its higher density.

获取价格

Fluorite Mining Processing Equipment Flow Chart Cases - JXSC

Relation to Mining (IMAR 7th Edition) In some areas, fluorite rich veins may be weathered to depths of as much as 75 m. Such weathered ore, a mixture of clay and fragments of fluorite and detached wall rock, may be mined open pit with draglines, scrapers, or power shovels to depths of as much as 50 m.

获取价格

Difference Of Metallurgical And Chemical Grade Fluorite Ore ...

6 之 Gravity separation method is mainly used to produce metallurgical grade fluorite lump ore.Sorting is carried out according to the specific gravity difference between fluorite ore and waste rock, and stratified according to specific gravity in gravity separation equipment such as jig separator.Thus, two kinds of minerals with different specific gravity are obtained, the one with

获取价格

Ultimate Guide for Magnetic Separation Method - Mining-pedia

Magnetic separation is carried out in the non-uniform magnetic field provided by the magnetic separation equipment. After the ore enters the separation space of the magnetic separation equipment, it moves along different paths under the combined action of magnetic force and mechanical force (including gravity, centrifugal force, fluid resistance, etc.) and we can

获取价格

Process and Principle of Magnetic Separation of Iron Ore

2021/6/26 Today, I will share with you the magnetic separation process of iron ore. Magnetic Separation Principle. ... Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals ...

获取价格

8 Types of Iron Ore Magnetic Separator - miningpedia

2022/3/25 Magnetic separation is the most common process in iron ore processing plant. Due to the difference in ore properties, the magnetic separation methods in actual production are also different, so different magnetic separators are also used. This article will introduce 8 common magnetic separators to you. 1. Magnetic separation column

获取价格

Jig Separator Gravity Separation of Tin Ore - JXSC Mineral

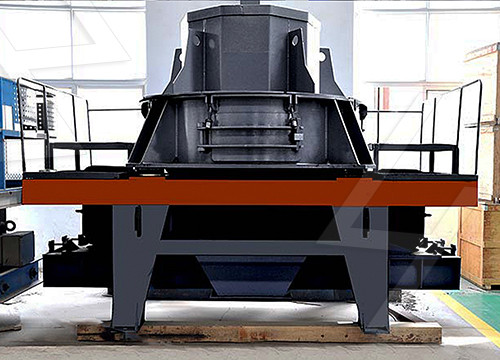

2024/1/4 This complete setup is Coltan(Ta-Nb), Tin, Tungsten Washing Concentration Plant. It is configured with a Vibrating Feeder to feed raw material and remove oversized rocks.. Trommel Scrubber to wash off the sticky mud from raw ores, and screen out three size ranges, the Ta-Nb, Tin grains will be released more easily from the cleaned ores.. Jig Separator is a

获取价格

High Gradient Magnetic Separator - JXSC Machinery

2. This high gradient magnetic separator has strong magnetic force and can effectively remove weak magnetic impurities in non-metallic ores; 3. The magnetic field gradient is large and adjustable, with high intensity, high grade of finished concentrate, and

获取价格

Magnetite Separation Production Line - Jinpeng Mining

Compared to other minerals , magnetite ore is easier to separate . We use normally permanent magnetic separator , magnetic pulley and magnetic dewatering tank ,these process are very easy . These years , with the enhance of requirement of fine particles and smelting industry , accelerated the magnetic technology , including the fine screen ,magnetic column and weak

获取价格

Comprehensive Guide to Magnetic Separator Maintenance

2023/8/30 When magnetic separators are well-maintained, they can efficiently remove contaminants, ensuring that the final product meets quality standards and regulatory requirements. 4. Safety and Compliance. Regular maintenance of magnetic separators contributes to a safe working environment.

获取价格