مسكن

>

Coal Preparation Crusher Cost

مسكن

>

Coal Preparation Crusher Cost

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Coal Preparation Crusher Cost

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

Jaw crusher. The jaw crushers are popular primary crushers for coal. They

How Much Does It Cost To Operate a Crusher?

How Much Does It Cost To Operate a Crusher? By Chris Nawalaniec Crushing equipment is the heart of an industrial material-processing system. The size reduction choice you make will have a profound impact on the profitability of

获取价格

price of coal crusher machine coal preparation process

Types of Coal Crushers. When it comes to coal crushers, there are several types available in

获取价格

Coal Preparation - an overview ScienceDirect Topics

Coal preparation includes crushing, screening, the removal of ash, washing, drying and blending and is an increasing vital part of the coal industries' activities. Although in some countries virgin coal is of sufficient uniformity that “run-of-mine” coal can be distributed straight to the user, in the majority of collieries (nearly all the ...

获取价格

Coal Crusher - Indicon Westfalia

As the recognized standard of responsible comminution engineering, Coal Crushers represent an integral value-add to any end-to-end Coal Preparation Plant – and in keeping with Indicon Westfalia’s commitment to providing the

获取价格

Coal Washing Process Plant - JXSC Machinery

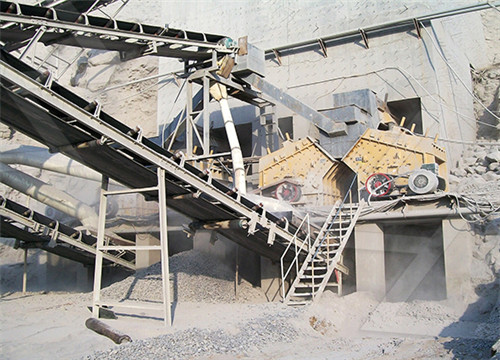

(1). Crushing: The large pieces of coal are sent to the jaw crusher by the vibrating feeder for rough crushing, and the conveyor transports the coarsely crushed materials to the impact crusher.The impact crusher is suitable for medium or

获取价格

Hard coal preparation in a single stage crushing circuit for ...

The article concerned the problem of coal preparation for gasification purposes. The main aim was to design the coal crushing circuit, which would produce the material within the particle size range between 0.5 and 5 mm. The one-stage crushing circuit

获取价格

Coal preparation plant - Wikipedia

A coal "washer" in Eastern Kentucky A modern coal breaker in Mahanoy City, Pennsylvania combines washing, crushing, grading, sorting, stockpiling, and shipping in one facility built into a stockpile of anthracite coal below a mountain top strip mine. A coal preparation plant (CPP; known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or

获取价格

crusher cost: coal preparation plant cost in india

Coal preparation plant cost , coal mining equipment Quotation of Coal Mining Equipment Production Line: Coal Crushing, Coal Screening, Coal Gravity separation.

获取价格

What Is Coal Preparation? - Energy.gov

Coal Preparation Workshop Ranchi, India ... the associated costs of transportation, handling, crushing, pulverizing and residual waste (flyash) disposal in the electricity generation are ... – Rough Scalping and Crushing • Level 2 – Coarse Coal (+1/2 inch) Cleaning only • Level 3 – Coarse and Fine Coal Cleaning

获取价格

Small Jaw Crusher for Laboratory and Small Mines: Efficient,

It is primarily used for medium and coarse crushing of coal, ores, and rocks in laboratories across sectors such as coal, electric power, chemical industry, metallurgy, geology, and more. This crusher is indispensable for scientific research units and industrial applications where precise material analysis and sample preparation are required.

获取价格

Coal preparation assessment fundamentals - ScienceDirect

2023/1/1 Coal preparation embraces all aspects of preparing a mined coal for the market. This chapter covers some of the fundamental aspects involved in assessing the requirements for coal sizing and cleaning, and perhaps the three most important quantitative analyses are the size distribution analysis, float and sink (FS) analysis for gravity separation, and flotation analysis

获取价格

How Much Does It Cost To Operate a Crusher? Resource Center

How Much Does It Cost To Operate a Crusher? By Chris Nawalaniec Crushing equipment is the heart of an industrial material-processing system. The size reduction choice you make will have a profound impact on the profitability of your business. When the right choice is made, you should expect many years of profitable operation. How do you make the right crusher choice?

获取价格

Coal Testing Equipment - Gilson Co. - GlobalGilson

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke using rotary-swing hammers. The enclosed steel cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low maintenance. ... Mixing Wheels are required in ASTM D2013 for laboratory preparation of certain coal samples. Mixing wheels ...

获取价格

Coal Preparation Plant Coal Preparation Process Coal Washing

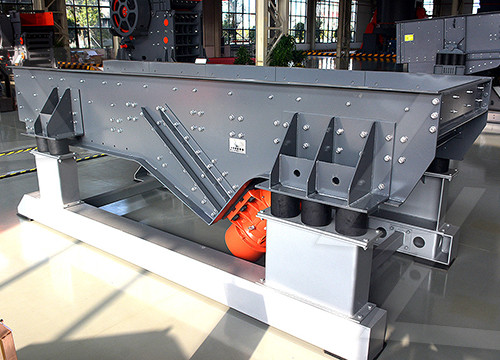

Crushing Screening: Raw coal is transported to crushing workshop by belt conveyor. First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm. +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with -50mm raw coal that under the vibrating screen.

获取价格

Cost Analysis at Russian Coal Mining Companies

2024/9/27 The composition and structure of the largest companies among Russia’s top 10 mining organizations are considered. Detailed economic information is given regarding the revenue and assets of those companies. Stages in implementing the production chain that moves resources in the coal industry are outlined. The cost structure at coal mining and processing

获取价格

(PDF) Coal Preparation Aimal Khan - Academia

It is therefore advisable to include some sort of grizzly screen, tramp magnets, or other oversize control to prevent such objects from reaching the crusher. 3.2.1.3. Hammer crushers Hammer mills These units are sometimes used for feed crushing in smaller coal preparation operations.

获取价格

Coal Testing Equipment - Gilson Co. - GlobalGilson

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke using rotary-swing hammers. The enclosed steel cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low maintenance. ... Mixing Wheels are required in ASTM D2013 for laboratory preparation of certain coal samples. Mixing wheels ...

获取价格

Coal Preparation Plant Coal Preparation Process

Crushing Screening: Raw coal is transported to crushing workshop by belt conveyor. First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm. +50mm materials and extra large gangue enter the crusher

获取价格

Cost Analysis at Russian Coal Mining Companies

2024/9/27 The composition and structure of the largest companies among Russia’s top 10 mining organizations are considered. Detailed economic information is given regarding the revenue and assets of those companies. Stages in implementing the production chain that moves resources in the coal industry are outlined. The cost structure at coal mining and processing

获取价格

(PDF) Coal Preparation Aimal Khan - Academia

It is therefore advisable to include some sort of grizzly screen, tramp magnets, or other oversize control to prevent such objects from reaching the crusher. 3.2.1.3. Hammer crushers Hammer mills These units are sometimes used for feed crushing in smaller coal preparation operations.

获取价格

CHAPTER 3 Coal Preparation and Cleaning - Springer

Coal Preparation and Cleaning T.D. WHEELOCK and R. MARKUSZEWSKI 1. INTRODUCTION Most coal requires some preparation before use. Preparation may range from simply crushing to provide a size consist suitable for certain types of boilers to extensive size reduction and cleaning to remove sulfur and ash-forming mineral matter.

获取价格

Coal Preparation Systems for Boilers - Springer

Also, the cost of a storage system is much more than that of a direct fired system. For these reasons, ... than pulverized coal «200 I'lm), a crusher-based coal preparation system is sufficient for the former. It is much simpler and less costly than that of a PC boiler. The fuel preparation plant of fluidized bed boiler comprises

获取价格

A review of state-of-the-art processing operations in coal preparation ...

2015/7/1 Coal preparation can be a costly portion of the raw material production chain, given the large throughput requirements and the variety of technologies needed to create a suitable product. As a result, coal preparation requires carefully engineered processing plants which employ low-cost solid–solid and solid–liquid separation processes.

获取价格

A system-wide approach to minimize the operational cost of

2018/12/12 The production cycle of open-cast coal mines generally includes drilling, blasting, loading, hauling and coal preparation activities. Individual optimization of these activities does not mean that the whole system is optimized. This paper proposes a cost model considering all activities in mining cycle and system-wide approach to minimize the total mining cost of

获取价格

Coal Processing Coal Preparation Coal Handling RPM Solutions

Coal crushing can include a two stage process, dependent on deposit size. Coal is crushed in a feeder breaker, a chain conveyor that breaks the biggest lumps. ... Typical steps in coal preparation include: Crushing; Screening into different size factions ... Reduce the transportation cost per unit weight of coal; Meet customers ...

获取价格

Optimizing Coal Preparation at PAO Koks Coke and Chemistry

2024/6/26 Coal preparation is the most important step in coke production. Coke production depends on smooth operation of the coal preparation shop. ... On the basis of operational experience and the maintenance and repair costs of the crushers, it was decided to manufacture the fourth crusher in the repair shop at PAO Koks, along with all necessary cast ...

获取价格

Better Tooth Performance Lowers Cost per Ton - Coal Age

2021/2/10 The benefits of increased uptime include reduced maintenance costs. For example, a coal prep plant in Utah with a roll crusher with steel teeth was spending 36 hours per week building up teeth as routine maintenance. The rolls would be replaced every six months with rebuilds from a local shop.

获取价格

Coal preparation plant - Wikiwand

A coal "washer" in Eastern Kentucky A modern coal breaker in Mahanoy City, Pennsylvania combines washing, crushing, grading, sorting, stockpiling, and shipping in one facility built into a stockpile of anthracite coal below a mountain top strip mine. The more of this waste material that can be removed from coal, the lower its total ash content, the greater its market value and the

获取价格

Design of coal preparation plants: problems and solutions

tive costs per ton of clean coal. The design of a secure, cost-effective and efficient system of coal preparation requires taking into account such factors as the initial data for flowsheets, the choice of equipment and the equipment arrangement. The flowsheet design is based on the data of complex research of washability and the

获取价格

Dense Medium Baths and Drum Separators - Springer

Power Costs, WEMCO Drum, Wing Tank system. 1.0 Coal Preparation and Dense Medium Baths - A Brief History Mechanised Coal preparation began in the 19th Century with the introduction of simple Coal Jigs, where a box containing a bed of Coal on a perforated steel bedplate was moved mechanically upwards and downwards.

获取价格