مسكن

>

Deep processing and reuse of coal slag

مسكن

>

Deep processing and reuse of coal slag

منتج

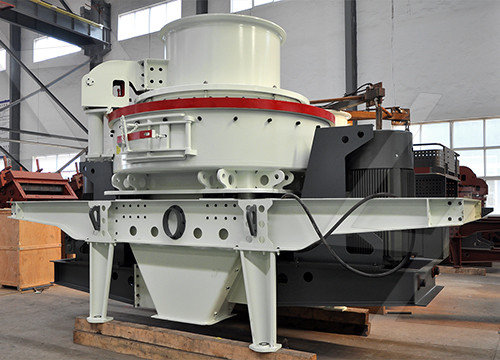

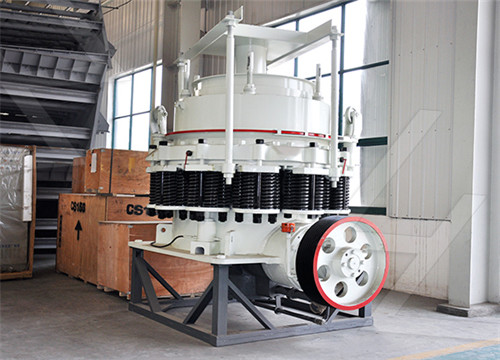

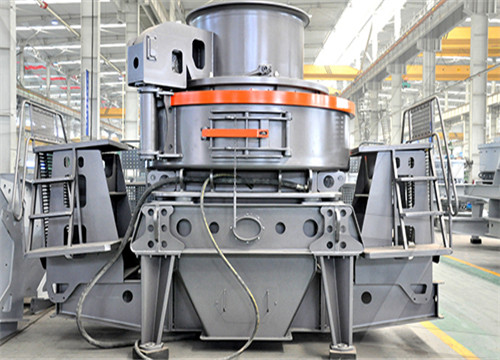

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Deep processing and reuse of coal slag

A review of sustainable utilization and prospect of coal gasification

2023/12/1 As the leading industry of coal chemical industry, Coal gasification plays an

获取价格

Acid-Alkali Deep Deashing and Alkali Activation of

Nowadays, coal gasification fine slag (CGFS) generated during the coal gasification process has become difficult to treat bulk solid waste. CGFS contains high levels of residual carbon, which is difficult to recycle due to the tight

获取价格

Efficient separation of coal gasification fine slag from Texaco ...

2024/4/19 Coal gasification fine slag (CGFS) is one of the by-products of coal

获取价格

Slag recycling and reuse – GREENY approach - Metso

2021/1/12 The reuse of slag should be organized at the site where the slag is stored, as any transport costs will increase the processing costs significantly. From the environmental point of view, the landfilling of slags is a significant

获取价格

Multiscale analysis of fine slag from pulverized coal gasification in ...

2024/2/3 Fine slag (FS) is an unavoidable by-product of coal gasification. FS, which is a

获取价格

Performance of Full-Component Coal Gasification Fine

2024/2/15 Ultrafine, highly active coal gasification slag (HCGS) was produced via a sustainable, green dry-ball-milling method. Coal gasification fine slag (CGS), a potential environmental pollutant, was used as a new source of

获取价格

Deep insight into phase transition and crystallization of high ...

2021/2/5 The treatment of high temperature molten slag usually involves a phase change cooling process coupled with crystallization behavior, which is a very challenging process and will significantly affect the high-temperature waste heat recovery, the vitreous content in slag, the quality of the as-cast slab, and the stable operation of the integrated ...

获取价格

Review of the characteristics and graded utilisation of coal ...

2021/7/1 Process for purifying coal gasification slag and system for realizing the process. CN Pat. (2018) 107641537 (in Chinese) Google Scholar [68] S.V. Vassilev, R. Menendez, A.G. Borrego, M. Diaz-Somoano, M.R. Martinez-Tarazona. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 3 ...

获取价格

The recycling and reuse of steelmaking slags — A review

2019/7/1 The volume instability caused by free lime exposure to moisture means that the reuse of steelmaking slag is often limited as many potential applications, and the leaching behavior of steelmaking slag is important for environmental considerations. ... fine iron ore particles are mixed with a small amount of coal (5% by weight), and the mixture ...

获取价格

Efficient and Safe Coal Ash Reuse Processing with Rotary Dryers

The proper equipment is crucial in increasing safety during coal ash drying for reuse. With technological advancements by companies like Heyl Patterson Thermal Processing, the potential risks associated with coal ash can be effectively managed while maximizing its beneficial reuse in various industries. Contact us for more information.

获取价格

The Effects of Pretreated Coal Gasification Slag Aggregates on the ...

2024/8/2 The integrated gasification combined cycle is a relatively new and eco-friendly power generation technology. However, this process produces coal gasification slag (CGS) as a by-product, which is usually landfilled or discarded. To enable efficient recycling of CGS, this study investigated the effects of using pretreated CGS as a fine aggregate on the quality and

获取价格

Processing and Reusing Technologies for Steelmaking Slag

About 40 million tons of steel slag a year, which is the by-product of iron and steel manufacture, is generated in Japan and the almost all the slag is reused for the materials, e.g. cement raw material, road base course material and civil engineering material, by effectively utilizing its characteristics such as chemical components and mechanical properties. Most of its purposes

获取价格

Deep insight into phase transition and crystallization of high ...

High temperature molten slags, such as blast furnace slag, mold flux, coal slag, etc., exist widely in the metal manufacturing and energy power industries and play important roles in equipment operation, energy saving and emissions reduction as well as resource reuse. The treatment of high temperature molten slag usually involves a phase change cooling process coupled with

获取价格

Acid-Alkali Deep Deashing and Alkali Activation of Coal

Nowadays, coal gasification fine slag (CGFS) generated during the coal gasification process has become difficult to treat bulk solid waste. CGFS contains high levels of residual carbon, which is difficult to recycle due to the tight binding of minerals with residual. In our study, the carbon source of active carbon (P-AC) was obtained by the molten-caustic leaching (MCL) method, in which ...

获取价格

On-site source-separation of microparticles and reuse of coal ...

2024/8/9 However, as an inevitable by-product, 15–20% solid residues including coal gasification fine slag (FS) and coal gasification coarse slag (CS) are produced [4], which poses a great threat to economic development and environment protection due to high annual emissions and improper disposals, such as stacking and landfill.

获取价格

(PDF) Industrial uses of slag. The use and re-use of iron and ...

2005/2/1 Hence, a collaborative processing of steelmaking slag and other P-bearing industrial solid wastes is proposed, providing a new solution for P recovery and the comprehensive utilization of ...

获取价格

Deep insight into phase transition and crystallization of high ...

2020/10/1 The treatment of high temperature molten slag usually involves a phase change cooling process coupled with crystallization behavior, which is a very challenging process and will significantly ...

获取价格

Characterization, carbon-ash separation and resource utilization of ...

2023/4/20 CGS is classified into coal gasification coarse slag (CGCS) and coal gasification fine slag (CGFS). The CGCS is directly discharged at the bottom of the gasifier, and its composition is mainly aluminosilicates in the amorphous glassy state with relatively low carbon content (Guo et al., 2014).CGCS can be used for many applications, such as cement, road

获取价格

Recovery of metal values from copper slag and reuse of

DOI: 10.1016/j.wasman.2017.09.024 Corpus ID: 30661972; Recovery of metal values from copper slag and reuse of residual secondary slag. @article{Sarfo2017RecoveryOM, title={Recovery of metal values from copper slag and reuse of residual secondary slag.}, author={Prince Sarfo and Avimanyu Das and Gary F. Wyss and Courtney Young},

获取价格

A review of sustainable utilization and prospect of coal gasification slag

2023/12/1 As the leading industry of coal chemical industry, Coal gasification plays an important role in efficient and clean utilization of coal. It is a process in which solid fuels such as coal, coke, or semi-coke react with gasifying agents under high temperature and pressure to produce gaseous products and a certain amount of slag (Aprianti et al., 2023; Xue et al., 2023;

获取价格

Deep insight into phase transition and crystallization of high ...

2020/10/1 The treatment of high temperature molten slag usually involves a phase change cooling process coupled with crystallization behavior, which is a very challenging process and will significantly ...

获取价格

Characterization, carbon-ash separation and resource utilization of ...

2023/4/20 CGS is classified into coal gasification coarse slag (CGCS) and coal gasification fine slag (CGFS). The CGCS is directly discharged at the bottom of the gasifier, and its composition is mainly aluminosilicates in the amorphous glassy state with relatively low carbon content (Guo et al., 2014).CGCS can be used for many applications, such as cement, road

获取价格

Recovery of metal values from copper slag and reuse of

DOI: 10.1016/j.wasman.2017.09.024 Corpus ID: 30661972; Recovery of metal values from copper slag and reuse of residual secondary slag. @article{Sarfo2017RecoveryOM, title={Recovery of metal values from copper slag and reuse of residual secondary slag.}, author={Prince Sarfo and Avimanyu Das and Gary F. Wyss and Courtney Young},

获取价格

A review of sustainable utilization and prospect of coal gasification slag

2023/12/1 As the leading industry of coal chemical industry, Coal gasification plays an important role in efficient and clean utilization of coal. It is a process in which solid fuels such as coal, coke, or semi-coke react with gasifying agents under high temperature and pressure to produce gaseous products and a certain amount of slag (Aprianti et al., 2023; Xue et al., 2023;

获取价格

Modification and resource utilization of coal gasification slag

2024/4/1 Coal gasification technology has led to a significant increase in CGS discharge and consequently, the disposal of gasified solid waste gasification slag has become a major concern [10].It is reported that, more than 70 million tons of CGS is produced every year in China [11].Only a very small part of the slag is used, while the vast majority of CGS is simply

获取价格

Preparation of coal gasification fine slag-based supercapacitive

2024/1/11 The coal gasification is the key process of clean usage of coal resource, which inevitably produces a large amount of coal gasification slag (CGS), and causes serious environmental pollution and ecological damage. The high ash content of coal gasification fine slag (CGFS) prevents the efficient utilization of residual carbon in CGFS. In this work, carbon-rich

获取价格

Enrichment and utilization of residual carbon from coal

2023/3/1 Slag is the main by-product of coal gasification. According to the difference in the discharge mode and particle size, coal gasification slag is mainly composed of two parts, namely coarse slag and fine slag (Pan et al., 2016).Herein, coarse slag is mainly discharged from the bottom of the gasifier, while fine slag is mainly from the dust removal device, including the

获取价格

Requirements and Policies - CT.gov

Applicable statewide for a particular material. Individual users must register for the GP and comply with its requirements. There are 2 Current BU GPs: Storage and Processing of Asphalt Roofing Shingle Waste for Beneficial Use and Recycling. Storage and Processing of Scrap Tires for Recycling and Beneficial Reuse. Copies of GPs, Registration forms, etc. available at:

获取价格

Review and Perspectives of Ash Slag Fluidity during Co

2024/1/2 The stable fluidity of slag at a high temperature is crucial for the long-period operation of an entrained-flow gasifier. The diversity and difference of coal ash make it difficult to meet the requirements for stable slagging in a gasifier. Consequently, coal blending or adding flux has been employed in the industry to improve the fluidity of coal ash slag. As a carbon

获取价格

Recent research progress on recycling metallurgical waste slag

2024/11/1 The utilization rate of SS exceeds that of LFS due to its lower basicity, although it remains considerably lower than the rates observed in developed countries in Europe and the United States, standing at approximately 30 % [4].Currently, the internal recycling of SS predominantly takes place within the smelting production process, serving purposes such as

获取价格

Processing Ash and Slag Wastes from Thermal Power Stations. Part 2

2018/11/29 For existing coal-fired power plants, current methods of utilizing ash and slag waste may be considered in addressing new environmental and economic risks. However, for new power sources, environmental considerations are much more important in selecting the coal-combustion technology. Technology based on a circulating fluidized bed is sometimes cited as

获取价格

Hazard-Free Treatment and Reuse of Magnesium Slag

48 2 Hazard-Free Treatment and Reuse of Magnesium Slag I. G. Farben Process: In this process, magnesium hydroxide and coke are evenly mixed and calcinated in shaft furnace. Chlorination is conducted to produce anhy-drous MgCl 2. As electrolytic raw material, it is electrolyzed to obtain magnesium with recycling of electrolytic byproduct Cl 2 ...

获取价格

Comprehensive review on metallurgical recycling and cleaning of copper slag

2021/1/28 Ni, Co can also be achieved in slag cleaning process. Reductive smelting of copper slag with addition of coal, pyrite (FeS 2 ) and fluxes (such as CaCO 3 ) in electric furnace is a potential ...

获取价格

Characteristics and environmental aspects of slag: A review

2015/6/1 Scientific interest in slag has been increasing steadily since the early 1990s. The number of slag studies that are referenced in this paper by publication date is shown in Fig. 1 (see Appendix A Summary of slag characterization references and type of data from each that was used in this paper, Appendix B Summary of slag application and reuse references for this

获取价格