مسكن

>

material balance around raw mill in cement

مسكن

>

material balance around raw mill in cement

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

material balance around raw mill in cement

(PDF) Analysis of material flow and consumption in

2015/8/1 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material

获取价格

Table 2 Mass balance of the raw mill under investigation.

Table 2 indicates that the total input materials used in the raw meal production were 2.48 kg/kg of raw meal, and that hot gas from the kiln and natural resources (limestone, silica, iron ore, and ...

获取价格

Heat Mass Balance in Cement Plant PPT - SlideShare

(PDF) Analysis of material flow and consumption in

2015/8/1 The material efficiency values for a raw mill, pyro-processing tower, rotary kiln, clink cooler, and cement mill are determined to be 36.69%, 34.24%, 39.24%, 29.76%, and 25.88%, respectively ...

获取价格

(PDF) Exergy Analysis of Cement Raw Mill Using

The hot gases enter the base of the mill and pass upwards through a louvered annular ring around the grinding table. The entrained fine material is carried by the air stream upwards into the classifier forming the upper part of the mill. ...

获取价格

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement

获取价格

Performance Evaluation of Vertical Roller Mill in Cement

Keywords: Vertical roller mill, cement grinding, performance evaluation INTRODUCTION Cement production is highly energy consuming process with energy utilization of around 110-150 kWh/t (Villa, 2005).

获取价格

Henan Mining Machinery and Equipment Manufacturer - Cement Raw Mill

material balance around raw mill in cement SBM. Popular QA for Ball mill heat balance. Q: I have a heating pad for my ball python and it wont stick under t A: You can either use duct tape or use a velcro. Cement raw materials grinding mill raw mill cement mill.

获取价格

Heat Mass Balance in Cement Plant PPT - SlideShare

2021/11/27 Heat Mass Balance in Cement Plant - Download as a PDF or view online for free ... 1.58 kg gas/kg material, capacity of mill-300 TPH coal mill 2.0 NA 200 Running hr-20 in a day;1.58 kg gas/kg material, capacity of mill-38 TPH Pre-heater 6.8 1.50 8691 Out let Temp-280 degree Standard flue gas flow at PH outlet -1.50 Nm3/kg for pet coke ...

获取价格

Mass Balance Reconciliation for Bilinear Systems: A Case Study of a Raw

2016/6/12 The cement industry is responsible for around 33.3 per . ... Material balances are fund amental to ... Stream flow rates and their several compositions are measured in a typical cement raw mill ...

获取价格

material balance around raw mill in cement - thenganilodge.co

material balance around raw mill in cement (PDF) Analysis of material flow and consumption in The material efficiency values for a raw mill, pyro-processing tower, rotary kiln, clink cooler, and cement mill are determined to be 36.69%, 34.24%, 39.24%, 29.76%, and 25.88%, respectively,...

获取价格

Vertical Raw Mill Heat Balance Excel Sheet - INFINITY FOR CEMENT EQUIPMENT

Vertical Raw Mill Heat Balance Excel Sheet . To Download the Below Excel sheet + most Important Cement Books and Guides from Famous companies click here now ... Raw material ( dry) 251,750.00 1,691,760.00: 35: 0.192: Raw material moisture ...

获取价格

Mass balance for cement production Download Scientific

This paper analyzed the eco-efficiency of concretes (water/cement ratio = 0.50; cement content=350 kg/m3, and slump = 7 cm) with blended cement containing 25% by weight calcined pozzolan obtained ...

获取价格

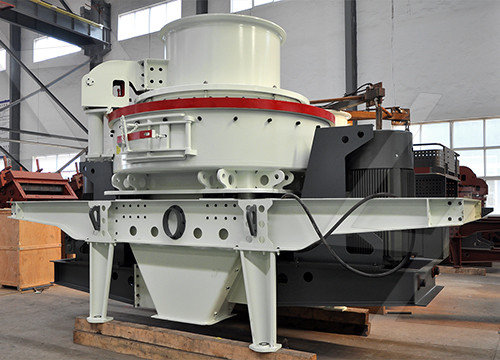

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant.Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one. It can be widely used in cement, electric power, metallurgy, chemical industry, non-metallic ore, and other industries.

获取价格

material balance around raw mill in cement - thenganilodge.co

material balance around raw mill in cement (PDF) Analysis of material flow and consumption in The material efficiency values for a raw mill, pyro-processing tower, rotary kiln, clink cooler, and cement mill are determined to be 36.69%, 34.24%, 39.24%, 29.76%, and 25.88%, respectively,...

获取价格

Vertical Raw Mill Heat Balance Excel Sheet

Vertical Raw Mill Heat Balance Excel Sheet . To Download the Below Excel sheet + most Important Cement Books and Guides from Famous companies click here now ... Raw material ( dry) 251,750.00 1,691,760.00: 35: 0.192: Raw material

获取价格

Mass balance for cement production Download

This paper analyzed the eco-efficiency of concretes (water/cement ratio = 0.50; cement content=350 kg/m3, and slump = 7 cm) with blended cement containing 25% by weight calcined pozzolan obtained ...

获取价格

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant.Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one. It can be widely used in cement, electric power, metallurgy, chemical industry, non-metallic ore, and other industries.

获取价格

Optimizing Raw Mills Performance PDF Mill (Grinding) Cement

Optimizing the raw materials selection and properties can significantly improve raw mill performance and capacity. Reducing the raw material size from 70mm to 30mm increased one mill's output by 14%, far exceeding theoretical predictions. Maintaining an optimal raw meal residue around 10-15% and moisture level of 0.25-1.0% also enhances performance.

获取价格

Engineering, Technology Applied Science Research Mass

The cement industry is responsible for around 33.3 per cent of industrial energy consumption in Morocco. It has ... is raw meal. Material balances are fundamental to the control of processing, particularly in the control of yields of the products. Equilibrium of the material balance equations ... Schematic diagram of a typical cement raw mill ...

获取价格

Thermodynamic Analysis of Raw Mill in Cement Industry Using Aspen Plus ...

2018/9/10 The simulator was used for the thermodynamic performance of a raw mill (RM) and raw materials preparation unit in a cement plant in Nigeria using actual operating data. The raw mill has a capacity ...

获取价格

Rawmill - Wikipedia

A medium-sized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the

获取价格

Preparation Of Cement Raw Material Cement Mill, Cement

AGICO Cement supplies cement equipment for cement raw material production as you need, such as cement mill, cement crusher, one-stop turnkey project, welcome to contact! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES RU.. Menu. Menu. Home; Cement Equipment.

获取价格

material balance around the raw mill in cement

material balance around raw mill in cement. Chapter 1 - Introduction to Cement Production The balance of cement used today consists of masonry cement, which is fifty ...There are two types of raw materials which are combined to make cement: ...The mixture of materials is finely ground in a raw mill.The resultant raw mix is burned in a rotary kiln at temperatures around 4482

获取价格

Sustainable Clinker and Cement Production by Using Alternative Fuels ...

Control of mill operation through analysis of composition and fineness of raw mill feed; ... Clinker analysis to check kiln operation and clinker quality and material balances; Analysis of finished cement to check mill operation, gypsum and SCM additions as well as the quality of the finished cement (example EN 197, ASTM C150, ASTM C595, and ...

获取价格

Ventilation Prediction for an Industrial Cement Raw Ball Mill by

2021/6/10 1. Introduction. In the cement industry, grinding is one of the most consuming energy stages in the production units. Around 65% of the total used electrical energy in a cement plant has to be utilized to grind raw materials, coal, and clinker [1,2].Through the process, many variables can affect the efficiency and productivity of this dry grinding procedure, such as the

获取价格

Vertical roller mill for raw Application p rocess materials

Vertical roller mill for raw materials Application p rocess Raw material process ... above the table or transported to separator by the gas blown around the table to hold them in the mill inside until desired particle size by clinkering process is gotten. This ... The basic management of the components of cement raw materials is to set the mixing

获取价格

Raw Material Drying-Grinding - Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills. Closed circuit ball mill with two compartments for ...

获取价格