مسكن

>

Magnesium oxide processing process

مسكن

>

Magnesium oxide processing process

منتج

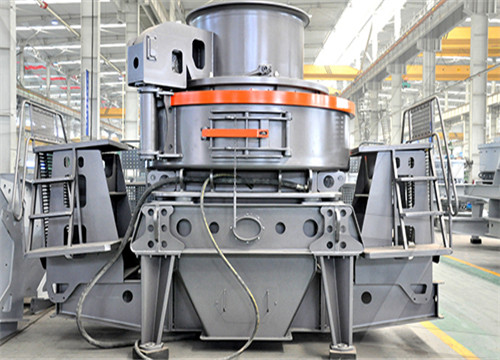

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Magnesium oxide processing process

Different Manufacturing Processes of Magnesium Oxide

2024/9/18 Lightly Calcined Magnesium Oxide. Production Process: Lightly calcined magnesium oxide, sometimes called caustic-calcined magnesium oxide, is produced by heating magnesium hydroxide at a lower temperature, around

获取价格

Process for producing magnesium oxide - Google Patents

High purity magnesium oxide is obtained from a magnesite-containing ore, the impurities of

获取价格

Magnesium processing Techniques Methods Britannica

OverviewHistoryOres and raw materialsMining and concentratingExtraction and refiningElectrolysisThermal reductionRefiningmagnesium processing, preparation of magnesium ore for use in various products.Magnesium (Mg) is a silvery white metal that is similar in appearance to aluminum but weighs one-third less. With a density of only 1.738 grams per cubic centimetre, it is the lightest structural metal known. It has a hexagonal close-packed (hcp) crystalline structure, so that, like most met在britannica上

Sustainable manufacturing process applied to produce

Different types of magnesium oxide are produced by using the dry process route, such as dead

获取价格

Magnesium Extraction From Magnesium Oxide Using Solid

Solid Oxide Membrane (SOM) Process for Magnesium Production-Leading to Magnesiothermic

获取价格

Production method for magnesium oxide - Google Patents

The present disclosure is a production method for magnesium oxide. This production method

获取价格

Process for the production of magnesium oxide - Google Patents

A process for the production of a magnesium oxide having high hydrolysis resistance and high

获取价格

Sustainable manufacturing process applied to produce

2020/4/2 The process of producing magnesium oxide could be considered as a sustainable manufacturing process due to the applied lower sintering temperature which leads to reduce cost, energy and pollution.

获取价格

Magnesium oxide production methods and production process,

2024/6/25 Manufacturing method of magnesium oxide I. Introduction Magnesium oxide

获取价格

Manufacture of magnesium oxide from sea water by Premier

The term periclase refers to natural magnesium oxide. In 1979, Premier Periclase established

获取价格

Magnesium oxide - Wikipedia

Magnesium oxide (Mg O), or magnesia, is a white hygroscopic solid mineral that occurs naturally as periclase and is a source of magnesium (see also oxide).It has an empirical formula of MgO and consists of a lattice of Mg 2+ ions and O 2− ions held together by ionic bonding. Magnesium hydroxide forms in the presence of water (MgO + H 2 O → Mg(OH) 2), but it can be reversed

获取价格

Magnesium Production Process Analysis of Novel, Sustainable

Magnesium Production Process Madison Rutherford, Gabriel Espinosa, and Lucien Wallace. ... internally from tin oxide –Some is MgF₂ to react with CaO, might recover some from bath out –Carbon anodes cost $150/T Mg, inert anodes would remove this cost - but add 2.2

获取价格

Pidgeon process - Wikipedia

Vapor-deposited magnesium crystals from the Pidgeon process. The Pidgeon process is a practical method for smelting magnesium.The most common method involves the raw material, dolomite being fed into an externally heated reduction tank and then thermally reduced to metallic magnesium using 75% ferrosilicon as a reducing agent in a vacuum. [1] Overall the processes

获取价格

Magnesium Oxide: Formation, Properties, And Applications

2024/9/24 Magnesium (Mg) is oxidized in a furnace or kiln to form magnesium oxide (MgO), a stable compound used in various industrial applications. The process involves heating magnesium sources like magnesium carbonate (MgCO3) or magnesium hydroxide (Mg(OH)2) under high temperatures, leading to the decomposition of these compounds and the release of

获取价格

Process for producing high purity magnesium oxide with dolomite

The invention discloses a process for producing high purity magnesium oxide with dolomite, comprising the steps of: subjecting dolomite to fragmentation, calcination, digestion, filtration, carbonization, solid-liquid separation, pyrolysis, basic magnesium carbonate drying and basic magnesium carbonate calcination, thus obtaining high purity magnesium oxide with CaO

获取价格

Magnesia (MgO) Production and Characterization, and Its

2020/10/23 oxide, MgO) is mainly produced from the calcination of magnesite in a process similar to the production of lime from limestone. A smaller proportion of the world’s MgO production comes from seawater

获取价格

World’s First Magnesium Extraction Process Production by

Castellanza, September 13, 2022 – Tenova, a leading developer and provider of sustainable solutions for the green transition of the metals industry, was awarded a contract by Latrobe Magnesium Limited (LMG), a company based in Australia. The scope of work is the engineering, supply, and supervision of the Magnesium Oxide (MgO) production plant at Latrobe Valley,

获取价格

Magnesium Smelting via the Pidgeon Process SpringerLink

2021/4/30 Magnesium oxide is reduced to magnesium vapor at this temperature and under this vacuum for 8–10 h; the magnesium oxide becomes crude magnesium after condensation. ... Xiaosi S (2011) Overview of magnesium production process. Shanxi Metall 03:1–4. Google Scholar Juan L, Wang J, Bi Z et al (2009) Evaluation method for clean production of ...

获取价格

Evolution of Primary Magnesium Metal Production Leads to the ...

2023/10/30 The emissions impact of the ATR process is dominated by where the magnesium oxide comes from, land or sea. The difference in emissions between post-industrial or post-consumer aluminum scrap feed also contributes to the overall footprint. In practice, these are levers with stark trade-offs between cost and embedded impact.

获取价格

Process for the production of magnesium oxide - Google Patents

the present invention relates to a process for the production of a magnesium oxide useful as a thermal conductivity improver of a resin, heat resistant material, electrical insulating material, sheathed heater filler, optical material, polishing material, etc., which has not only the physical properties inherent to magnesium oxide such as a high melting point (about 2,800°C), high

获取价格

Introduction to magnesium alloy processing technology and development ...

2018/9/1 Protection of molten magnesium with the help of flux was used before the development of gaseous protection. A small quantity of flux (20% KCl, 50% MgCl 2, 15% MgO, 15% CaF 2 wt%) is placed at the bottom of the crucible and preheated to dull red hot [4].Some more amount of flux is slightly sprinkled during melting, holding and casting [3].After the

获取价格

Magnesium Oxide - an overview ScienceDirect Topics

The principal phases of magnesium in seawater are chlorides and sulphates and the production process is initiated by the addition of a strong base to facilitate the precipitation of magnesium hydroxide (Mg ... Magnesium oxide (MgO, magnesia) is an ionic compound widely used as a substrate for diamond film, ...

获取价格

Magnesia - Forms, Applications and Production Processes

2002/4/3 Fused Magnesia Production Process. Magnesite (magnesium carbonate MgCO 3) is converted into magnesia by the application of heat which drives off carbon dioxide (CO 2), thereby converting the carbonate to the oxide of magnesium (MgO).

获取价格

Method for producing magnesium metal from magnesium oxide

A method is provided for the electrolytic production of magnesium metal. The method is highly economical in that the method permits the use of magnesium oxide as a feed stock for the electrolytic process. The method uses a rare earth chloride as a constituent of the electrolyte bath. The rare earth chloride spontaneously reacts with the magnesium oxide to form magnesium

获取价格

Introduction to magnesium alloy processing technology and development ...

2018/9/1 Protection of molten magnesium with the help of flux was used before the development of gaseous protection. A small quantity of flux (20% KCl, 50% MgCl 2, 15% MgO, 15% CaF 2 wt%) is placed at the bottom of the crucible and preheated to dull red hot [4].Some more amount of flux is slightly sprinkled during melting, holding and casting [3].After the

获取价格

Magnesium Oxide - an overview ScienceDirect Topics

The principal phases of magnesium in seawater are chlorides and sulphates and the production process is initiated by the addition of a strong base to facilitate the precipitation of magnesium hydroxide (Mg ... Magnesium oxide (MgO, magnesia) is an ionic compound widely used as a substrate for diamond film, ...

获取价格

Magnesia - Forms, Applications and Production

2002/4/3 Fused Magnesia Production Process. Magnesite (magnesium carbonate MgCO 3) is converted into magnesia by the application of heat which drives off carbon dioxide (CO 2), thereby converting the carbonate to the

获取价格

Method for producing magnesium metal from magnesium oxide

A method is provided for the electrolytic production of magnesium metal. The method is highly economical in that the method permits the use of magnesium oxide as a feed stock for the electrolytic process. The method uses a rare earth chloride as a constituent of the electrolyte bath. The rare earth chloride spontaneously reacts with the magnesium oxide to form magnesium

获取价格

Analysis of the production process of pharmaceutical grade magnesium oxide

2024/10/30 The production process of pharmaceutical grade magnesium oxide is a complex and refined process involving multiple steps and strict quality control.The following is a detailed analysis of the production process of pharmaceutical grade magnesium oxide:. Raw material preparation: Choose high-purity magnesium ore or magnesium containing

获取价格

Sustainable production of biodiesel from waste cooking oil using ...

2024/9/24 Materials. Waste cooking oil was initially gathered from sources that were used at home. It was a blend of palm and sunflower oil. Chemicals are utilised without any additional preprocessing.

获取价格

Development of a novel electrolytic process for producing high

2021/9/15 The current electrolytic processes for magnesium (Mg) metal have several disadvantages, such as anhydrous magnesium chloride (MgCl 2) preparation and generation of harmful chlorine (Cl 2) gas.To overcome these drawbacks, a novel Mg production process to produce high-purity Mg metal directly from magnesium oxide (MgO) was investigated in this

获取价格

Hydrometallurgical processing of magnesium minerals – A

2021/5/1 In particular, the Pidgeon process produces magnesium metal, first by calcining dolomite to produce a blend of magnesium oxide and calcium oxide, and then by reducing the oxides with ferrosilicon FeSi to produce magnesium gas (Li et al. 2013), which is subsequently condensed into solid metal.

获取价格

Magnesium Metallurgy - SpringerLink

2023/6/11 In 1808, H. David of England made magnesium amalgam from the mixture of electrolytic mercury and magnesium oxide, and obtained magnesium for the first time. This substance is named after the place where magnesium oxide was obtained at that time – the Greek city of Magnesia. ... also called external heating magnesium production process. By ...

获取价格

Magnesium Oxide Production by Plasma Chemical Conversion

2022/11/1 It was found that the conversion process of magnesium fluoride to magnesium oxide has a relatively high degree of decomposition of magnesium fluoride fraction ≤75 µm. The use of the proposed processing method makes it possible to obtain pure magnesium oxide as a commercial product and to utilize fluorine-containing industrial waste.

获取价格

Magnesium Oxide - an overview ScienceDirect Topics

19.2.1 Production of MgO of Very High Purity. Magnesium oxide is most frequently obtained by thermal decomposition of magnesium hydroxide or different magnesium salts at temperatures of 550–1000°C. For example, Mg ... In the magnesium oxide process, MgO in the slurry is used the same way limestone or lime is used in the lime scrubbing ...

获取价格

Figure . Process flow diagram of synthesis of MgO powder.

For example, diluted magnesium hydroxide generated from an electrolysis process was calcined at a temperature of 500°C for 4 h to obtain a magnesium oxide product with a purity of 91.21% [48].

获取价格

Review on the Silicothermic Process for Primary Magnesium Production

2022/12/5 Pidgeon process as one of the silicothermic processes is the main method for Mg production. This paper aims at reviewing the research and improvement of the Pidgeon process toward solving three problems encountered in the process: slow chemical reaction rate, low heat transfer efficiency, and semi-continuous production. Specifically, the reaction

获取价格

A comparison of carbon footprints of magnesium oxide and magnesium

2018/11/20 In this study, modelling the carbon footprints of magnesium oxide and magnesium hydroxide (>99% purity) production based on technologies treating bischofite brines (e.g. Aman process) and serpentinite ores (e.g. Magnifin process) was performed. The two technologies have been utilised by many producers around the world to deliver specialty

获取价格