منتج

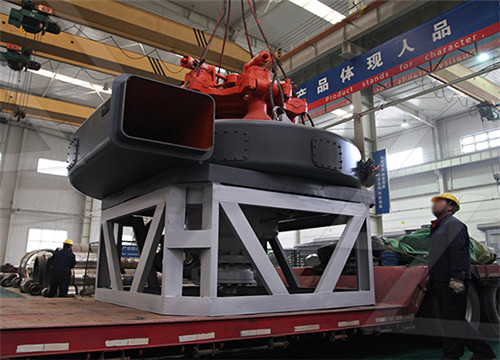

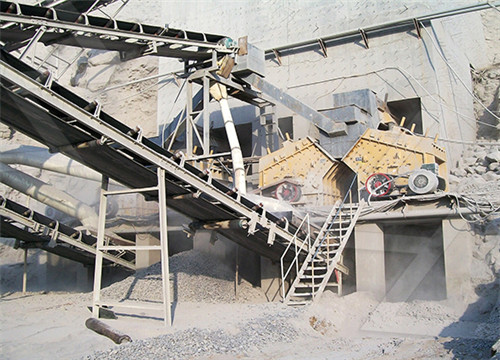

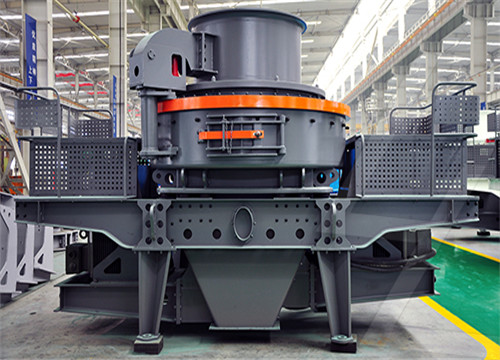

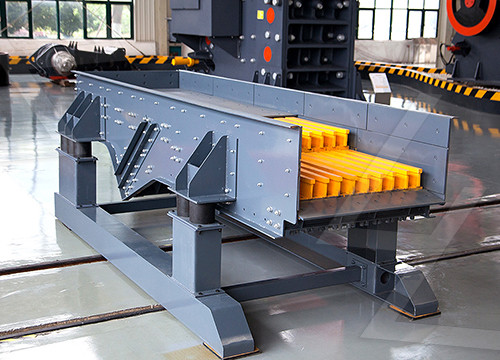

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

fine coal washeries

Sustainability of coal mines: Separation of clean coal from the fine ...

2021/5/1 Tailings coal from the tailings pond of two different coal washeries namely

获取价格

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA Dr. D.D.HALDAR Deputy

获取价格

Mineral Beneficiation and Processing of Coal SpringerLink

2021/5/11 Present-day coal washeries are equipped with various advanced equipment

获取价格

Beneficiation of Coking Coal Fines Lying in the Waste ... - Springer

2024/11/19 It was observed that coal fines from washery contain major elements like SiO 2, Al 2 O 3, and Fe 2 O 3 of which Silica is the major constituent having >55%. A representative sample of the coal fines was subjected to detailed washability investigations to evaluate the theoretical yield at the desired ash level. The tests were undertaken at a ...

获取价格

Coal Washeries in India - Energy Portal

Capacity utilization of a washery depends on various governing factors, such as plant efficiency, market demand, coal availability, cost of washing etc. which are broadly the business decisions to be taken by the concern washery operator/

获取价格

Flotation response of coal washery reject fines:

About five tonnes of coking coal washery fines are col-lected from Chasnala coal washery, Dhanbad, from the mid-zone of the tailing pond (Figure 1). As received, bulk

获取价格

Fine coal recovery from washery tailings in Turkey by oil

2018/3/1 Beneficiation of fine coal by using traditional gravity methods cannot be applied efficiently due to limited effect of gravity on small coal particles [14]. Flotation has been the most well accepted and used method for fine coal cleaning in coal washeries [15].

获取价格

EIA Guidance Manual for the Coal Washeries - Corpbiz Advisors

2023/2/20 This device can clean fine coal at a low cost, but its limited capacity is only adequate on particles with specific gravities larger than 1.5. Froth Flotation; The most common method for cleaning particles is froth flotation. Froth flotation cells make use of differences in the surface properties of coal and refuse to purify ultra-fine coal.

获取价格

(PDF) Dewatering of fine coal and refuse slurries-problems and ...

2009/9/1 Handling and disposal of high volume of fine coal tailings is a biggest challenge for coal washeries. Separation of clean coal by density separation and flotation shows limited yields of 23–28% ...

获取价格

Sustainability of coal mines: Separation of clean coal from the fine ...

2021/1/31 In this study, agglomeration process was applied for recovery of fine coals from coal washery tailings containing remarkable amount of fine coal. Negative effect of fine clays during recovery was ...

获取价格

John Finlay Coal Washery Design Engineering Dry Coal Sorting

Heavy media cyclones separate coal and rock to produce clean coal, while vibrating screens grade coal and remove impurities nd centrifuges dewater coal fines and slurries. Conslutancy John Finlay has over 50 years of experience in the coal industry, involved in 125 Coal Washery EPC Projects as a leading consultant.

获取价格

Fine coal recovery from washery tailings in Turkey by oil

2018/3/1 The study of fine coal recovery from washery tailings by Yasar et al. [9] showed that 57.60% of the sulfur could be removed, and Ken et al. [10] showed that 60.51% of total sulfur and 58.70% of pyritic sulfur could be effectively removed by oil-agglomeration for Indian high-sulfur coal using linseed oil. Froth flotation based on the difference ...

获取价格

Economic and Environmental Impact of Coal Washing in India

Use of coal at the same time raises environmental concerns. The impacts of increased coal utilisation will have increased environmental impacts from emissions of air pollutants during coal mining, coal transportation and coal combustion, contamination of the surface and ground water, forest loss due to mining, etc.

获取价格

9-Guidelines For Coal Washeries PDF Coal Air Pollution

This document provides operating guidelines for processing consent applications to establish coal washeries in Orissa, India. Key points include: 1) Coal washeries are encouraged to be located near coal mines and integrated steel/sponge iron plants to use washery rejects for power generation. 2) Minimum washery size is set at 1 million tons per year to allow for mechanized,

获取价格

Sedimentation and electro-osmotic dewatering of coal-washery

1981/10/1 The particulate matter present in coal washery tailings is a mixture of fine coal and mineral matter, and as both components have negative zeta potentials in water'2"14 both are presumably contributing to the electro-osmosis. The technique could therefore also be applicable to the recovered fine coal and the high-ash tailings from slimes that ...

获取价格

USAGE OF WASHED COAL IN INDIA: ISSUES AND

growth of “power” coal washing and in the processing of small and fine coking coal in India. Yet, power coal washing is not gaining the momentum and coking coal washing is at best limping. In this author’s opinion, the barriers to the major expansion of coal beneficiation industry and usage of washed coal in India is:

获取价格

EXECUTIVE SUMMARY - DSIR

Bath/Jig/Cyclone but without beneficiation of fine coal (-0.5mm) except in Kathara washery. Fines were dumped in ponds for recovery. Later periods saw introduction of beneficiation in fine coal also in almost all washeries including retrofitting in old washeries. Present trends are pre-washing sized raw coal, efforts to upgrade fines and

获取价格

9-Guidelines For Coal Washeries PDF Coal Air

This document provides operating guidelines for processing consent applications to establish coal washeries in Orissa, India. Key points include: 1) Coal washeries are encouraged to be located near coal mines and integrated steel/sponge

获取价格

Sedimentation and electro-osmotic dewatering of coal-washery

1981/10/1 The particulate matter present in coal washery tailings is a mixture of fine coal and mineral matter, and as both components have negative zeta potentials in water'2"14 both are presumably contributing to the electro-osmosis. The technique could therefore also be applicable to the recovered fine coal and the high-ash tailings from slimes that ...

获取价格

USAGE OF WASHED COAL IN INDIA: ISSUES AND

growth of “power” coal washing and in the processing of small and fine coking coal in India. Yet, power coal washing is not gaining the momentum and coking coal washing is at best limping. In this author’s opinion, the barriers to the major expansion of coal beneficiation industry and usage of washed coal in India is:

获取价格

EXECUTIVE SUMMARY - DSIR

Bath/Jig/Cyclone but without beneficiation of fine coal (-0.5mm) except in Kathara washery. Fines were dumped in ponds for recovery. Later periods saw introduction of beneficiation in fine coal also in almost all washeries including retrofitting in old washeries. Present trends are pre-washing sized raw coal, efforts to upgrade fines and

获取价格

Characterisation and beneficiation of some Indian coal fines

fines judiciously and in view of scarcity of coking coal, these fines are to be beneficiated to reduce their ash content. Flotation is only known method to beneficiate these fines commercially. The present paper deals with some of the coal fines generated at different washeries viz. Sudamdih, Patherdih, Kathara and West Bokaro. The coal fines ...

获取价格

Coal preparation Plants (Washeries) Illawarra Heritage Trail

The combined feed to the washery coal bin comprised 90.7% of raw coal at 24.3% ash and 24.6% volatile matter. The discharge from this bin was fed to a 1/8” screen. ... The fine coal flotation cells for BC Plants are now dedicated to C module with the two Delkor horizontal belt vacuum filters now servicing both D and C modules. A significant ...

获取价格

Implementation of Fine Screening Technology in Fine Coal

Dewatering of Coal Washery Tailings and Elimination of Tailing s Ponds . At a coal washery in India, fine tailings (typically 0.5mm) from the flotation circuit were thickened in a thickener and ...

获取价格

Coal washing scenario in India and future prospects

2016/6/28 Recurring losses in the coking coal washeries is another principal deterrent in capacity utilization (Sarkar et al. 2015). On further investigation, it was revealed that these washeries are operating at very poor yield; and in many of the public sector washeries fine coal circuit is not in operation (Sarkar et al. 2015; Alam and Patel 2012 ...

获取价格

Use of aggloflotation for fine coal recovery from washery tailings

2019/12/23 In coal washeries, a considerable amount of fine coal is sent to tailings ponds in Turkey as well as in the World. Fine coal in the tailings should be recovered due to its economic value and ...

获取价格

Coal beneficiation: theory and practice - ScienceDirect

2023/1/1 From fine coal sump pump, the slurry is fed to a cluster of raw coal classifying cyclones. In coking coal washeries, the overflow from the classifying cyclones is sent to froth flotation cells. However, in noncoking coal washery, the cyclone overflow is

获取价格

Characterisation of coal washery effluent and optimisation of ...

problem in the management of coal washery effluent is its high load of suspended solids which mainly consists of coal fines (hydrophobic), shale, slates, clay minerals and other impurities (hydrophilic) associated with raw coal (Duong et al. 2000). Coal and other fines are generated duetotransport,handling,stocking,machine-crushingand

获取价格

Fine coal recovery from washery tailings in Turkey ... - دانشیاری

In Turkey, coal washeries discharge huge amount of fine coal containing tailings. Loss of economically valuable energy source and negative environmental effects of accumulated tailings necessitate the recovery of fine coals from these tailings. In the present study, the

获取价格

Fine Coal Recovery from Washery Tailings in Turkey by

2017/12/1 In Turkey, coal washeries discharge huge amount of fine coal containing tailings. Loss of economically valuable energy source and negative environmental effects of accumulated tailings necessitate ...

获取价格

COLUMN FLOTATION TECHNOLOGY FOR THE

30 Million tonnes of coal is washed every year in Indian coal washeries. 20 - 30% of coal in the form of fines are produced and are being lost as tailings. Veryfew washeries have the facilities to treatthese coal fines. The standard existing coal beneficiation techniques are not effective to recover fine coal from these coal washery tailings. ...

获取价格