مسكن

>

ore crushing 120 mesh method

مسكن

>

ore crushing 120 mesh method

منتج

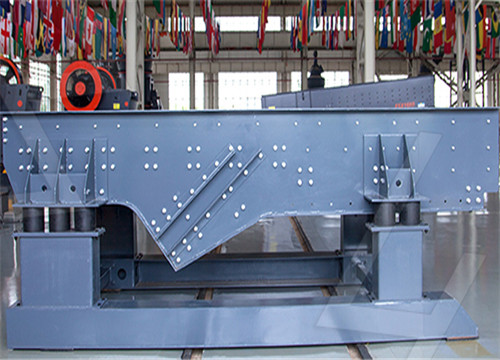

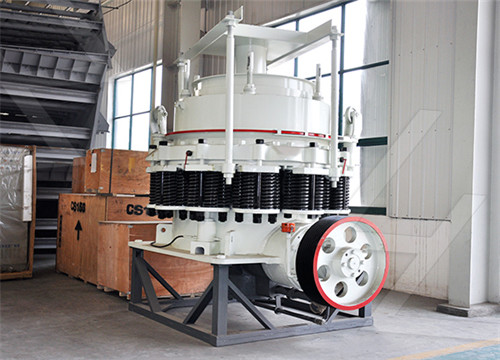

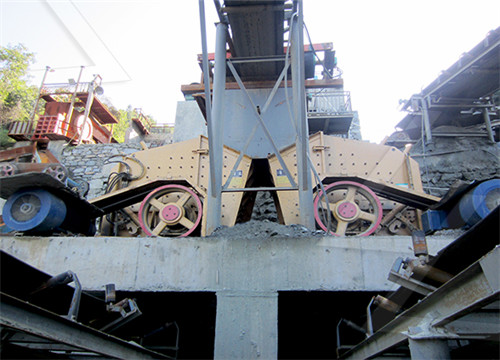

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

ore crushing 120 mesh method

Research on discrete element parameter calibration of ore

Similarly, many scholars have proposed important theories on ore crushing to provide a basis

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Crushing of Ore and MineralsCrushing EquipmentJaw CrusherJaw Crusher FundamentalsJaw CrushersFeeding Jaw CrushersGyratory Crushers Normally the size reduction by crushing is of limited importance besides the top size of the product going to grinding.This means that the number of crushing stages can be reduced depending on the feed size accepted by primary grinding stage.在millopsmunity.uaf上Reduction Ratio: 4:1 to 7:1

Crushing and Screening Handbook - AusIMM

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you

获取价格

Ore Crushing - SpringerLink

2023/7/22 The maximum crushing ratio of coarse crushing is about three. The main

获取价格

Method of selecting optimum parameters of ore crushing

2016/3/20 FIELD: process engineering. SUBSTANCE: invention relates to ore

获取价格

Numerical Study on Crushing Law of Iron Ore Under Different

2021/10/21 Abstract. Ore crushing is one of the most important steps in mine

获取价格

LECTURE NOTES - KIIT Polytechnic

The ore lumps from the mines have the lump size of 10 - 100 cm while the individual minerals

获取价格

Industrial Solutions Jaw crushers - ThyssenKrupp

method, in preparation for finish crushing or conveying. ... • Ore mining industry • Ore crushing

获取价格

Optimal mesh design methodology considering geometric

The performance of the primary crusher is key to the ore beneficiation process. Optimisation

获取价格

SIZE REDUCTION BY CRUSHING METHODS

2017/3/4 SIZE REDUCTION BY CRUSHING METHODS. March 2017; DOI:10.13140 ... we propose a method for tracking the ore particle size distribution on the conveyor based on the U-Net neural network that was ...

获取价格

Crushing and Screening Handbook - AusIMM

crushing process. The design of our certifi ed wear parts starts with CAD simulations of the crusher cavity, which is the heart of the crush-ing process. By computer based planning and continuous quality control of the casting we can guarantee premium material quality, which translates into improved wear life and a higher

获取价格

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more

获取价格

Copper Ore Crushing, Grinding Flotation - 911Metallurgist

2017/5/21 Crushing and Grinding. You will note that the Oracle Ridge project has utilized a two-stage crushing circuit with a double acting jaw crusher and cone crusher. In order to utilize this system, the jaw crusher is oversized to produce all -5 material for the cone mill with a screen in closed circuit.

获取价格

Overview of Mineral Processing Methods - ResearchGate

2015/8/3 In this context, the effect of different process variables such as particle size (-60 + 100 mesh; -100 + 200 mesh and -200 + 270 mesh) and shaking speed (80 rpm, 100 rpm and 120 rpm) was analysed.

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that improves (benefits) the

获取价格

Ball Mills - Mt Baker Mining and Metals

They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation. Sold individually or as part of our turn-key ore processing system.

获取价格

How Ores have Resistance to Crushing - 911Metallurgist

2016/3/28 The method adopted for computing the results is that of Rittinger, based on the law that work done in crushing is proportional to the surface exposed by the operation, or to the reciprocal of the diameter. For plotting the screen tests, the mesh (reciprocal of diameter) and the cumulative per cent, of oversize are used as coordinates.

获取价格

An Introduction to Uranium Ore Processing - Utah

of ore in each truckload can be determined. As soon as sufficient tonnage has accumulated, the shipper's IDt is fed to' the crushing and sampling plant. AlmDst withDut exception, primary crushing is done by jaw crushers which reduce run Df mine ore (12 inch max ... imum) to apprDximately 2 inches. In SDme plants samp,

获取价格

sbm coal mining methods introduction ore crusher mesh

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

获取价格

How to Process Copper Ore: Beneficiation Methods and Equipment

2023/3/13 Copper ore beneficiation methods Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 0.15-0.2mm. Copper ore crushing ...

获取价格

Bauxite - Ore Crushing Solutions -

has manufactured large amount of mining equipments to global countries, such as jaw crusher series, impact crusher series, cone crusher series and the grinding mill series, etc. mining equipments have been exported to more than 130 countries which are widely applied in mining industry including the bauxite crushing.

获取价格

Ore Sampling Methods: Good Proper - 911Metallurgist

2017/2/21 If we imagine a lot, for instance, of Cripple Creek ore, composed entirely of barren gangue and one solitary piece of calaverite, it would be manifestly impossible to sample such a lot of ore without crushing, since in any subdivision either the sample or the reject would contain all of the mineral.

获取价格

Optimization of roller teeth based on the analysis of the

the crusher, the size of the crushed product directly affects the economic interests of users, so it is necessary to study the crushing mechanism of sinter ore. In the field of crushing, there are many numerical calcu-lation methods for particle crushing, and the finite element method is one of the most widely used methods at present.

获取价格

How to Process Copper Ore: Beneficiation Methods

2023/3/13 Copper ore beneficiation methods Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials

获取价格

Bauxite - Ore Crushing Solutions -

has manufactured large amount of mining equipments to global countries, such as jaw crusher series, impact crusher series, cone crusher series and the grinding mill series, etc. mining equipments have been exported to more than 130 countries which are widely applied in mining industry including the bauxite crushing.

获取价格

Ore Sampling Methods: Good Proper - 911Metallurgist

2017/2/21 If we imagine a lot, for instance, of Cripple Creek ore, composed entirely of barren gangue and one solitary piece of calaverite, it would be manifestly impossible to sample such a lot of ore without crushing, since in any subdivision either the sample or the reject would contain all of the mineral.

获取价格

Optimization of roller teeth based on the analysis of the

the crusher, the size of the crushed product directly affects the economic interests of users, so it is necessary to study the crushing mechanism of sinter ore. In the field of crushing, there are many numerical calcu-lation methods for particle crushing, and the finite element method is one of the most widely used methods at present.

获取价格

crusher/sbm rock grinding machine 60 120 mesh sieve.md at

sbm rock grinding machine 60 120 mesh sieveFlotation of low grade phosphate ore ScienceDirect First,the mineral was pretreated through grinding,sorting and discarding slimes.The presence of free carbonates in phosphoric rock leads to considerably higher a high vibration machine equipped with a set of fine ASTM sieves,with the.Sieve ASTM Mineral size (mesh) (µm) 20

获取价格

Predictive modeling of crushing power in cone crushers with the ...

2024/11/1 Comminution consists of the progressive reduction of ore size in successive stages. This operation is the most energy-consuming in mineral processing, utilizing up to 50% of the total energy expended in this industry [1].Among the challenges this process presents are the inappropriate design of the process control, unwanted segregation, and ore variability from run

获取价格

Uranium Ore Processing Methods - 911Metallurgist

2016/5/12 The process flowsheet of Uranium generally outlines the latest proven processes for uranium concentration known as “Resin In Pulp” more commonly referred to as RIP To date it is not applicable to ores containing vanadium, where the vanadium must be recovered.. Crushing Uranium Ore. Depending upon ore shipment schedules, it is desirable to operate the

获取价格

Mercury Ore Processing - 911Metallurgist

2016/4/27 A Mercury Ore Beneficiation Process Flowsheet Crushing Circuit. Conventional single stage crushing comprises this section, since the tonnage is less than 100 tons per day. The mine ore is fed from the coarse bin by means of a Apron Feeder to the Jaw Crusher. Crusher feed passes over a grizzly with an opening similar to the crusher setting.

获取价格

320 Mesh Ore Crusher For Fine Ore Processing - mining-asia

2024/11/16 Ore crushing plays a pivotal role in mining and material processing industries. When fine-grade ore materials are needed, a 320-mesh ore crusher is an invaluable tool. This article delves into the specifics of this type of crusher, its

获取价格

Open Access proceedings Journal of Physics: Conference series

Impact crushing is the most important ore crushing method. There are three classical theories to predict the fragmentation of ore under impacting load, namely, surface area theory, volume theory ...

获取价格

Method of selecting optimum parameters of ore crushing

2016/3/20 FIELD: process engineering. SUBSTANCE: invention relates to ore processing and may be used at mining plants for concentration of minerals. Proposed method comprises crushing ore samples, sizing crushed samples, fractionation of grain-size categories to content of valuable component. After fractionation, slime fractions of valuable mineral is integrated with

获取价格

Comminution and classification technologies of iron ore

2022/1/1 Some examples of different iron ore crushing and screening flowsheets are provided below: ... The target grind size of the circuits varies between the 90% and 95% passing 500 mesh (32 μm) depending on the feed ore characteristics and operating conditions (Rajala et al., ... Methods for crushing operational control.

获取价格

Commonly used ore lithium extraction process method - CM

2022/12/16 The methods of lithium extraction from ore mainly include sulfuric acid method, sulfate method, lime sintering method, chlorination roasting method, etc. ... of spodumene and roast it at 1000-1100 °C for 30 minutes; Spodumene milling: it is finely ground to less than 200 mesh by a lithium ore mill; Acidified roasting, sulfuric acid (93%-98% ...

获取价格

11.24 Metallic Minerals Processing - U.S. Environmental

The number of crushing steps necessary to reduce ore to the proper size vary with the type of ore. Hard ores, including some copper, gold, iron, and molybdenum ores, may require as much as a tertiary crushing. Softer ores, such as some uranium, bauxite, and titanium/zirconium ores, require little or no crushing.

获取价格