مسكن

>

pulveriser المعدنية peratation

مسكن

>

pulveriser المعدنية peratation

منتج

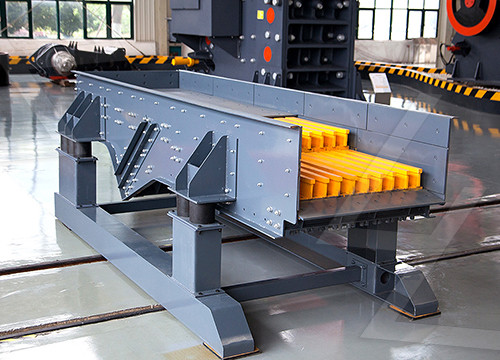

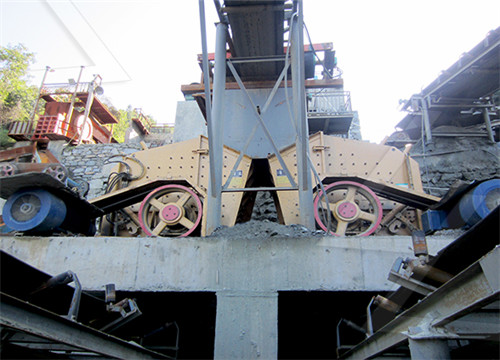

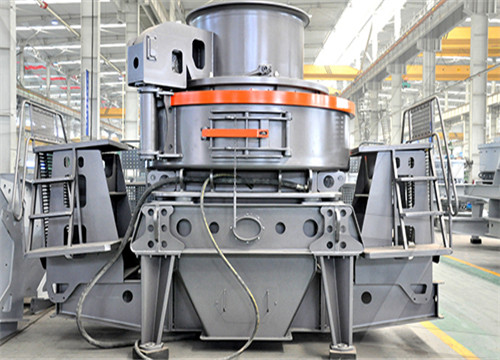

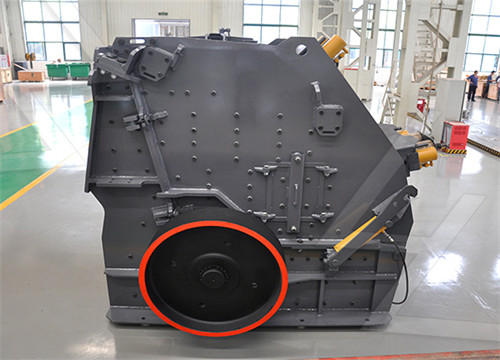

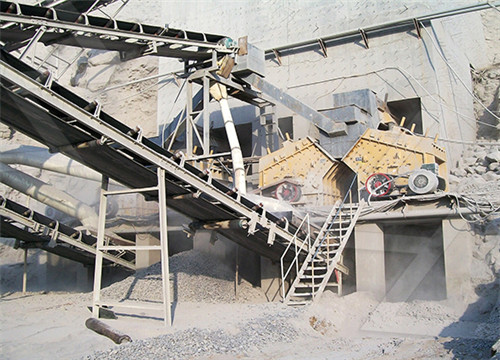

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

pulveriser المعدنية peratation

coal pulveriser PPT - SlideShare

2013/11/23 This document provides a summary of a presentation on ball and tube mills. It discusses the types of coal and reasons for pulverizing coal. It then describes the construction and operating principles of ball and tube mills,

获取价格

Pulverisation – Size Reduction Techniques, Types, Components,

These are slow-speed pulverizers. Mineral, cement and chemical industries use grinding mills

获取价格

Pulveriser Mill Performance Analysis Optimisation in Super

Pulverizer as shown in fig.1 is used in power plant to reduce the size of the incoming raw coal

获取价格

Optimization and Development of Pulverization Machine

A Pulverizer is a machine whose purpose is to shred or crush total material into lower pieces

获取价格

Optimum Operation and Maintenance of EL Pulverizers

mean fuel flow between each pulverizer’s separate fuel lines. • Pipe to pipe clean air balance within ±2% of the mean pipe velocity. • Air to fuel ratio of 1.75 to 1.8 pounds of air per pound of fuel. • Pulverizer to pulverizer mass air and fuel balance within ±5%. • Pulverizer outlet temperature of 160°F or higher.

获取价格

Operation and Maintenance Manual Hydraulic Pulverizer

The suitable carrier must be selected taking the weight and hydraulic system of the pulverizer into consideration. The carrier may fall over if the pulverizer is installed on the carrier, which does not fit the pulverizer. All hydraulic lines for the pulverizer use must satisfy the specification and quality provided in page 15, “5.2.

获取价格

Classifiers: The Brains of the Operation - Bradley

2021/12/16 All classifiers have an efficiency rating, reflecting how well they separate material. Some are very efficient while others are less so. Inefficient classifiers are unable to achieve a good fine/coarse separation. This means

获取价格

Operation instruction of pulverizer - Toolots

The device is a special pulverizer for synthetic resin runner residue and gate residue. 1.2 Users and clothing Please wear safety shoes during maintenance. Please do not disassemble, clean, or operate anyone other than the operator. Avoid easily involved clothes and wear gloves to prevent cuts. Use air gun cleaning, dust flying in the air ...

获取价格

Coal Pulverizer – Power Plant Pall Corporation

Hot air forced through the bottom of the pulverizing chamber removes unwanted moisture and transports the pulverized coal dust up through the top of the pulverizer and out the exhaust pipes directly to the burner. The more recent coal pulverizer designs are Vertical Roller Mills. Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer.

获取价格

Pulverizer Fineness and Capacity Enhancements at

capability can be used to increase the pulverizer and boiler capacity with the present coal or to maintain the present boiler load with a coal that is more difficult to pulverize. At Danskammer, the existing pulverizer capacity was increased by more than 15 percent while the coal particles larger than 50 mesh were essentially eliminated.

获取价格

Mechanical Operation Lab and Disc Pulverizer Manufacturer

Mechmin - Mechanical Operation Lab, Disc Pulverizer Planetary Ball Mill Manufacturer from Thane, Maharashtra, India. Mechmin. Bhayandar East, Thane, Maharashtra. GST No. 27AIGPY7555G1ZM. TrustSEAL Verified. Call 08045911089 90% Response Rate. SEND EMAIL. X. Planetary Ball Mill Machine.

获取价格

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance. The mill wear and

获取价格

OPERATING MANUAL Sepor Mini-Pulverizer - - Custom

pulverizer thoroughly, being careful to wipe all oil from the grinding plates and interior. The Mini-Pulverizer can be adjusted to the de- sired mesh by means of an adjusting hand wheel at the feed end of the pulverizer. By turning the hand wheel, the space between the grinding plates can be adjusted, and subsequently, the

获取价格

Operation and Maintenance Manual Hydraulic Pulverizer

The suitable carrier must be selected taking the weight and hydraulic system of the pulverizer into consideration. The carrier may fall over if the pulverizer is installed on the carrier, which does not fit the pulverizer. All hydraulic lines for the pulverizer use must satisfy the specification and quality provided in page 15, “5.2.

获取价格

Development and Performance Evaluation of a Pulverizer for

2021/9/6 The pulverizer was fabricated using locally available materials. Its performance evaluation gave 400kg/h throughput, 96% crushing efficiency and 96% efficiency based on the required particle size.

获取价格

Analisis Pola Pengoperasian Mill Pulverizer DI Pltu I Jawa Tengah ...

9 Gambar 4.Mill pulverizer tampak dari luar..... 10 Gambar 5.Arti dari typr HP 963 yang digunakan di PLTU Rembang ..... 11 Gambar 6.Komponen utama mill pulverizer..... 13 Gambar 7.Bowl dan grinding mill pulverizer ..... 14 Gambar 8.Grinding roll mill pulvezer..... 14 Gambar 9.Coal fineness test ..... 17 Gambar 10.Tyipical finenes/hubungan ...

获取价格

Mikro Pulverizer - Hosokawa Alpine

Mikro Pulverizers are high-speed hammer mills designed for continuous operation in harsh environments at peripheral speeds of up to 100 m/s. The product can be fed by means of feed metering screws, a suction intake, an injector assembly or can alternatively be gravity fed, dependent on ...

获取价格

Operating Manual - houseindustriesinc

The Pulverizer, in one operation, will prepare a seedbed, break up clods, incorporate chemicals, level the ridges and fill in the small low places in your fields. Farmers say the Pulverizer will do the same leveling as a 40’ land plane, but unlike a land plane, it will not pack the ground.

获取价格

Development and Performance Evaluation of a

2021/9/6 The pulverizer was fabricated using locally available materials. Its performance evaluation gave 400kg/h throughput, 96% crushing efficiency and 96% efficiency based on the required particle size.

获取价格

Analisis Pola Pengoperasian Mill Pulverizer DI Pltu I Jawa Tengah ...

9 Gambar 4.Mill pulverizer tampak dari luar..... 10 Gambar 5.Arti dari typr HP 963 yang digunakan di PLTU Rembang ..... 11 Gambar 6.Komponen utama mill pulverizer..... 13 Gambar 7.Bowl dan grinding mill pulverizer ..... 14 Gambar 8.Grinding roll mill pulvezer..... 14 Gambar 9.Coal fineness test ..... 17 Gambar 10.Tyipical finenes/hubungan ...

获取价格

Mikro Pulverizer - Hosokawa Alpine

Mikro Pulverizers are high-speed hammer mills designed for continuous operation in harsh environments at peripheral speeds of up to 100 m/s. The product can be fed by means of feed metering screws, a suction intake, an injector assembly or can alternatively be gravity fed, dependent on ...

获取价格

Operating Manual - houseindustriesinc

The Pulverizer, in one operation, will prepare a seedbed, break up clods, incorporate chemicals, level the ridges and fill in the small low places in your fields. Farmers say the Pulverizer will do the same leveling as a 40’ land plane, but unlike a land plane, it will not pack the ground.

获取价格

DESIGN AND FABRICATION OF A MILL PULVERIZER

A conventional mill pulveriser is a device consisting of a rotating head with free- swinging hammers, which reduce rock, grains or similarly hard objects to a predetermined size through a perforated screen [Sci-Tech Dictionary, 2003]. A mill pulveriser commonly known as a screenless hammer mill is like a regular hammer mills, is used to pound ...

获取价格

SWFL75.102 .128 VERTICAL-SHAFT PULVERIZER OPERATION

Spec.:Rotor dia. of pulverizer:750mm Model code:Vertical Variety code:Pulverizer Professional code:feed machinery 1.4 OPERATION CONDITIONS The following conditions must be accorded with when using this machine: 1.4.1 Pulverizer should be installed in basement or on the ground floor with room temperature between 5℃ and 40℃.

获取价格

BW ROLL WHEEL PULVERIZERS - Babcock Wilcox

Today, with more than 1,100 BW Roll Wheel pulverizers sold world-wide and six different sizes burning a variety of coals, BW has the proven design and operating experience to meet your specific project requirements. This performance has made the BW Roll Wheel pulverizer the pulverizer of choice for coal-fired boiler operators and owners.

获取价格

JK Pulverizer – Manufacturer of Good Quality Pulverizers like

J K Pulveriser are Manufacturer of Good Quality Pulverisers like Hammer Mill, Ultra ne Pulveriser ,Double Chamber Pulveriser and Impact Pulveriser. The pioneer in the eld meets your needs for variety of applications through a chain of processes such as Pre – Crushing to micro ne grinding, grading and handling of bulk powder materials with ...

获取价格

ANALISIS POLA PENGOPERASIAN MILL PULVERIZER DI PLTU I

Jumlah mill pulverizer yang beroperasi dan seberapa besar coal flow pada feeder sangat ditentukan oleh tingkat pembebanan yang dialokasikan oleh P3B dan kondisi batubara yang digunakan. Perubahan pola operasi mill pulverizer (manuver) memberikan dampak terhadap perubahan tingkat kestabilan dan keandalan unit, penggunaan/konsumsi pemakaian ...

获取价格

Operation and Maintenance Manual Hydraulic Pulverizer

The suitable carrier must be selected taking the weight and hydraulic system of the pulverizer into consideration. The carrier may fall over if the pulverizer is installed on the carrier, which does not fit the pulverizer. All hydraulic lines for the pulverizer use must satisfy the specification and quality provided in page 15, “5.2.

获取价格

15572 Riley POP Pulverizer Services Combustion

pulverizer optimization programs, and makes Riley Power uniquely qualifi ed to work on all pulverizer systems, regardless of the original manufacturer. TEST METHODS The measurement of individual coal line velocities, density and mass fl ow is typically done with Riley Power’s portable Pf-FLO III system,

获取价格

Selecting the Right Concrete Pulverizer for Your Mobile Crushing ...

2023/11/24 A concrete pulverizer, an essential excavator attachment, effortlessly fragments concrete into minute fragments while slicing through interlaced rebar. This enables the concrete to effortlessly descend rather than clinging to the rebar. Featuring a fixed jaw and a dynamic jaw, it empowers operators to effortlessly handle concrete structures like slabs, walls,

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

Corporation has recently acquired a European-designed vertical roller pulverizer, embodying some unique features not found in other medium-speed pulverizers. This paper presents a comparison of the Riley Vertical Roller Mill with Riley's two other pulverizer designs— a low-speed ball tube mill and a high-speed attrition pulverizer.

获取价格

Coal Pulverizer Design Upgrades to Meet the Demands of

Babcock Power Inc. company, has been developing improved coal pulverizer technology during the past several years to meet these challenging demands. All three (3) types of coal pulverizer systems supplied by RPI originally designed for low, medium and high- speed pulverization have undergone design upgrades and improvements. These machines

获取价格