مسكن

>

coal dust for cement factories

مسكن

>

coal dust for cement factories

منتج

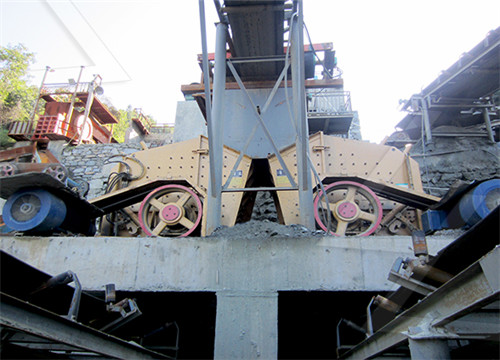

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

coal dust for cement factories

Coal Dust Explosions in the Cement Industry - Texas AM

Amin N. Alameddin1 and Steven J. Luzik2 Coal Dust Explosions in the Cement Industry REFERENCE: Alameddin, A. N. and Luzik, S. J.,fiCoal Dust Explosions in the Cement Industry,fl Industrial Dust Explosions, ASTM STP 958, Kenneth L. Cashdollar and Martin

获取价格

Coal Mill Safety In Cement Production Industries Coal

Coal Mill Safety In Cement Production Industries. It may come as a surprise, but cement industry is not capturing nearly as many coal dust explosions that actually occur. These incidents are often reported as boiler explosions or something

获取价格

Coal utilisation in the cement and concrete industries

2013/1/1 As of 2009, world cement output was estimated at 3.04 billion tonnes (metric tons). 6 China represents 56.1% of the world’s output while the USA represents 2.0%. 7 Fuel used by the US cement industry is 60% coal, 13% petroleum coke, and 3%, natural gas. 8 According to the US Energy Information Administration (EIA), the manufacture of cement ...

获取价格

Coal Dust Explosions in the Cement Industry - Mine Safety

Amin N. Alameddin1 and Steven J. Luzik2 Coal Dust Explosions in the Cement Industry REFERENCE: Alameddin, A. N. and Luzik, S. J.,fiCoal Dust Explosions in the Cement Industry,fl Industrial Dust Explosions, ASTM STP 958, Kenneth L. Cashdollar and Martin Hertzberg, Eds., American Society for Testing and Materials, Philadelphia, 1987, pp. 217-233.

获取价格

Coal Dust Explosions in the Cement Industry - ASTM International

Coal Dust Explosions in the Cement Industry Source. The number of coal fired industrial systems and utility power plants is rapidly increasing because of the high cost and uncertain availability of fuel oil and natural gas. For many cement producers in the United States, the conversion from fuel oil and natural gas to pulverized coal has been ...

获取价格

Coal Mill Safety In Cement Production Industries Coal Mill Safety ...

It may come as a surprise, but cement industry is not capturing nearly as many coal dust explosions that actually occur. These incidents are often reported as boiler explosions or something else because there is no mention of the fuel involved. ... static electricity can become a problem even with coal dust. Conclusion. Cement associations ...

获取价格

Coal utilization in the cement and concrete industries

2023/1/1 The utilization of coal in the cement and concrete industries takes three basic forms: (1) as a fuel in the production of cement clinker; (2) ash produced by burning coal in power stations is used as a component in cement rotary kiln feeds; (3) ash produced by burning coal in power stations is used as a mineral additive in concrete mixes.

获取价格

Dust Emission Monitoring in Cement Plant Mills: A Case Study in

Keywords: cement industry, PM, dust emissions, cement factories. 1. Introduction ... and power utilities (the coal mill and the power generators) [2,3]. Recent improvements in cement production processes and pollution control technologies have reduced pollutant emissions into the atmosphere. However, even with the best methods, the amount of ...

获取价格

Using coal waste to create sustainable concrete - ScienceDaily

2018/7/12 Researchers have created a sustainable alternative to traditional concrete using coal fly ash, a waste product of coal-based electricity generation. Share: Facebook Twitter Pinterest LinkedIN Email

获取价格

Coal Dust Explosions in the Cement Industry Industrial Dust ...

For many cement producers in the United States, the conversion from fuel oil and natural gas to pulverized coal has been difficult, frustrating, and in a few cases, very costly. This study deals mainly with coal safety requirements in the cement industry which accounts for a very small percentage of coal usage in pulverized coal firing systems.

获取价格

What Is The Difference Between Direct Coal-Fired Systems

Most systems in the cement industry work with low oxygen levels. They can take air with 3% oxygen from the preconsigner and feed it to the mill, which normally has an inert atmosphere. ... with coal dust. Conclusion Vincent recommended that cement associations get involved in improving safety in their coal-milling systems. The Wood Pellet

获取价格

Coal utilisation in the cement and concrete industries

2013/1/1 Replacing 20% of coal by biomass could also reduce the fossil emissions by 0.5 MtCO 2 /yr (6.2% of in-state industrial emissions) without making changes to the facilities. In Pennsylvania, heavy industry (cement, lime, glass, and steelmaking) emits about 9.4 MtCO 2 eq/yr. Most of the facilities are located near sedimentary basins, facilitating ...

获取价格

Explosions in Cement Plants - OQQSA

the last ten years due to explosions. Coal dust explosions were the cause of twenty-seven losses. Forty-seven percent of kiln losses occurred in the cement industry. A typical plant layout of a coal burning cement plant is shown in the next diagram. The equipment shown in red are the ones most likely to have explosions and the need for

获取价格

Report to Congress on Cement Kiln Dust: Study Findings and

The cement industry burns large amounts of high Btu fuels during the manufacturing process, primarily coal and other fossil fuels. In 1990, however, 23 facilities also burned hazardous ... EPA's analysis of cement kiln dust chemistry shows that CKD does contain toxic constituents, including metals and organic by-products. ...

获取价格

The 6 Main Process Fans in Cement factory

Cement industry uses large number of cooling fans usually between 5 to 15 in one clinker line based on the kiln capacity. Cooling fans are used to blow cold air to the cooler and to cool the clinker from 1500oC to 100oC. ... NOx and Sox along with some dust particles. Coal mill fans: In cement industry coal mill fans are used to supply required ...

获取价格

Cement Dust - an overview ScienceDirect Topics

Carbon sequestration potential of cement kiln dust: Mechanisms, methodologies, and applications. Saheed Kolawole Adekunle, in Journal of Cleaner Production, 2024. 3.1 Overview. Cement kiln dust (CKD), a type of cement dust, is a fine-grained by-product generated during the manufacturing of cement clinkers.It results from the chemical reactions within a cement kiln

获取价格

Explosions in Cement Plants - OQQSA

the last ten years due to explosions. Coal dust explosions were the cause of twenty-seven losses. Forty-seven percent of kiln losses occurred in the cement industry. A typical plant layout of a coal burning cement plant is shown in the next diagram. The equipment shown in red are the ones most likely to have explosions and the need for

获取价格

Report to Congress on Cement Kiln Dust: Study Findings and

The cement industry burns large amounts of high Btu fuels during the manufacturing process, primarily coal and other fossil fuels. In 1990, however, 23 facilities also burned hazardous ... EPA's analysis of cement kiln dust chemistry shows that CKD does contain toxic constituents, including metals and organic by-products. ...

获取价格

The 6 Main Process Fans in Cement factory

Cement industry uses large number of cooling fans usually between 5 to 15 in one clinker line based on the kiln capacity. Cooling fans are used to blow cold air to the cooler and to cool the clinker from 1500oC to 100oC. ... NOx and Sox

获取价格

Cement Dust - an overview ScienceDirect Topics

Carbon sequestration potential of cement kiln dust: Mechanisms, methodologies, and applications. Saheed Kolawole Adekunle, in Journal of Cleaner Production, 2024. 3.1 Overview. Cement kiln dust (CKD), a type of cement dust, is a fine-grained by-product generated during the manufacturing of cement clinkers.It results from the chemical reactions within a cement kiln

获取价格

How to Control Air Pollution in the Cement Industry - Oizom

2024/2/7 India’s cement industry links with other sectors, such as infrastructure, construction, housing, transportation, coal, power, steel, etc. It has a significant role in implementing Government flagship schemes and visions like housing for all, smart cities, concrete highways, dedicated freight corridors (DFC), the clean India mission, ultra-mega power

获取价格

Industrial Fan solutions for Cement industry applications

2021/2/25 In the cement industry coal mill fans are used to supply the required air for burning coal and remove the exhaust gases produced after burning. This is where the coal is grinded into the proper size to be fed into the burner. ... Dust Collector fans are the main equipment of dust removal systems in cement plants. They offer the power source to ...

获取价格

Fuels in the cement industry - INFINITY FOR CEMENT EQUIPMENT

Lepol kilns are fired with the following mix: 40 % lig nite and 60 % bituminous coal. The cement industry of the USSR uses coal from nearby coal mines. Often, this coal is of inferior quality, e. g. dust coal and coal mud. Table 18.3. con tains information about properties of coal used in the cited cement plants. Solid fuels- Coal

获取价格

Transition From Coal to Alternative Fuels in Cement Production Dust

In today’s episode of the Dust Safety Science podcast, Vincent Grosskopf, founder of Coal Mill Safety, talks about the changes in cement production moving from coal to alternative fuels, including hazards that need to be addressed. “What is happening in the cement industry is that everybody is thinking and talking about decarbonization, and one of the possibilities the

获取价格

Fire and Explosion Risks in Cement Manufacturing Plants

Cement manufacturing is a crucial industry in many countries throughout the world. ... Coal dust is a combustible dust that can easily explode when all the elements that cause fire are present. Bag Filters. Dust explosion, static electricity, spontaneous combustion, and high-temperature materials passing through the filters can cause fire or ...

获取价格

ASPECTS REGARDING DUST EMISSIONS AT CEMENT

The main sources of dust in the cement industry are stacks of the kiln system. Other dust emissions occur in the various pre-processing / grinding processes (raw materials, fuels, cement). ... 11. dosing system; 12. filter with coal mill dust removal bags; 13. burner; 14. extension furnace; 15.primary air fan; 16.electrofilter for the grill ...

获取价格

Deep decarbonisation of industry: The cement sector

Deep decarbonisation of industry: The cement sector Cement sector overview Cement is the binding agent of concrete, the most widely used construction material in the world. The cement sector is a major greenhouse gas emitter, ... coal and oil), waste fuels and biomass. While biomass usage has tripled since 2007, it currently only accounts

获取价格

Air Pollution Control in Cement: Solutions Impact - Techflow

2023/9/22 Prevention and control of dust: The priority in the cement industry is to minimize the increase in ambient particulate levels by reducing the mass load emitted from the stacks, from fugitive emissions, and from other sources. Collection and recycling of dust in the kiln gases is required to improve the efficiency of the operation and to reduce ...

获取价格

Strategising Dust Management - Indian Cement Review

2024/4/17 ICR delves into the multifaceted aspects of dust control in cement manufacturing, from environmental and health hazards to regulatory standards and innovative technologies. By exploring dust generation sources, control technologies and regulatory frameworks, it highlights the critical importance of effective dust management practices. Dust

获取价格

Coal for cement: Present and future trends - Global Cement

2016/3/1 Coal consumption in the cement industry will continue to vary according to market prices and availability and, as for other uses, will be more prevalent in developing markets than mature ones. Even with the rise of alternative fuels and low oil and gas prices, it is clear that coal will have a very large role to play in the most-rapidly growing ...

获取价格