مسكن

>

bowl mill raw coal pulverizers

مسكن

>

bowl mill raw coal pulverizers

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

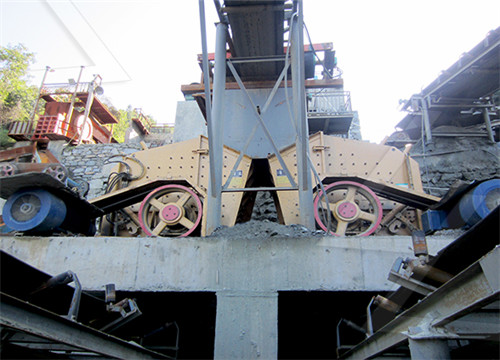

bowl mill raw coal pulverizers

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

IntroductionTypes of Coal PulveriserOperation of Bowl Mill PulveriserOperation of Ball Mill PulveriserThe main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling systemthrough coal feeder into a pre-determined size in order to increase the surface area of the coal. If the coal is not pulverised, the coal might not burn completely, thus resulting in wastage of fuel. 在coalhandlingplants上

Bowl Mill (Pulverizer) in Thermal Power Plant

2024/11/20 The Bowl Mill, also known as a pulverizer, incorporates the best features of

获取价格

Improving Coal Pulverizer Performance and Reliability - Pall

type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive. Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal. Raw coal enters the top of the pulverizer through the raw coal feed pipe ...

获取价格

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

1.5 Mill Wear and Ash Content in Raw Coal The coal is abrasive in nature due to the presence of hard materials like pyrites, α quartz etc., Due to the grinding ... BHEL for evaluation of coal pulverizer 1003 XRP Bowl Mills shown at Figure 1, for guaranteed performance at a 500 MW capacity NTPC thermal power plant. The cross section of the coal ...

获取价格

“Blueprint” Your Pulverizer for Improved Performance

that article explained, the capacity of a coal pulverizer is a complex function of the fuel fineness desired, the coal’s Hargrove Grind-ablity Index (HGI), and the coal’s raw feed size and moisture content (see Figure 3 in “Finessing Fuel Fineness”). Plant operators can only improve throughput of

获取价格

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl mill.Other grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring mill.

获取价格

Coal Pulverizer – Power Plant Pall Corporation

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the bowl). ... Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then ...

获取价格

Bowl Mill (Pulverizer) in Thermal Power Plant

2024/11/20 The Bowl Mill, also known as a pulverizer, incorporates the best features of various coal grinding systems, making it an efficient and reliable choice for. ... Supplies raw coal to the bowl and returns oversized particles for further grinding. Pressure Spring Assembly: Applies necessary pressure for effective grinding. ...

获取价格

Coal Pulverizer – Power Plant Pall Corporation

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the bowl). ... Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then ...

获取价格

Presentation ON Pulveriser: Presented by Debasis Mahapatra PDF Mill

The document discusses pulverizers, which are equipment used to pulverize coal into a fine powder for steam generation in boilers. It describes the types of pulverizers like ball tube mills, bowl mills, and impact mills. It explains the advantages of pulverized coal firing and discusses components like raw coal feeding, drying, grinding, classifying, and transporting. Key points

获取价格

BW ROLL WHEEL PULVERIZERS - Babcock Wilcox

Successfully managing the assets of today’s coal-fired power plant requires an understanding of the many components that make up a complete system. Reliable coal pulverizer performance is one element that is essential for sustained responsive power plant operation. More than the name has changed Since introducing the roll wheel pulverizer ...

获取价格

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012/11/17 15. 10.Bowl Mill Bowl mills are employed to pulverize the pre-crushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill output can be easily varied, as per the turndown ratio from its minimum to maximum load. Crushed raw coal at a controlled rate is fed into the revolving bowl of the Bowl Mill. Centrifugal force feeds

获取价格

HP Bowl type mills-power plant equipment

4. Selection method. The selection method of standard HP coal pulverizer can adopt computer software for accurate and detailed selection. Users only need to provide raw coal data, boiler coal consumption, pulverized coal fineness and number of coal mills to the manufacturer, and the professional technical personnel of the manufacturer will feed back the selection results to the

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

A COMPARISON OF THREE TYPES OF COAL PULVERIZERS by L.M. BENSON, Senior Engineer Fuel Burning Product Development and C.A. PENTERSON, Manager Fuel Burning Product Development ... FLS has successfully placed in operation their own VRM's, grinding coal or raw meal, with mill capacities ranging from 7 to 300 tons per hour.

获取价格

Pulverizer Plant OM Aspects - eecpowerindia

Pulverizer Plant OM Aspects Dr. T K Ray NTPC Limited E-mail: rayt3@asme ... Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Model no. Base capacity(T/Hr) ... Mill output at raw coal moisture and at Coal HGI 100-110 31 . Fineness Requirement 32 . Duocast Roll .

获取价格

Mill Inerting and Pulverizer/Mill Explosion Mitigation

start-up, shutdown, mill trips and interruptions in raw coal feed. – Its well known the the risk of mill explosion is highest during these ... COMMON CAUSE OF MILL FIRES: COAL SPILLAGE UNDER THE BOWL. 500°F - 700°F . Air-to-Fuel Ratio by Design ~1.8:1 Air-to-Fuel Ratio . ... pulverizer or raw coal in the high temperature under bowl

获取价格

HP Bowl type mills-power plant equipment

4. Selection method. The selection method of standard HP coal pulverizer can adopt computer software for accurate and detailed selection. Users only need to provide raw coal data, boiler coal consumption, pulverized coal fineness and

获取价格

A Comparison of Three Types of Coal Pulverizers - Babcock

A COMPARISON OF THREE TYPES OF COAL PULVERIZERS by L.M. BENSON, Senior Engineer Fuel Burning Product Development and C.A. PENTERSON, Manager Fuel Burning Product Development ... FLS has successfully placed in operation their own VRM's, grinding coal or raw meal, with mill capacities ranging from 7 to 300 tons per hour.

获取价格

Pulverizer Plant OM Aspects - eecpowerindia

Pulverizer Plant OM Aspects Dr. T K Ray NTPC Limited E-mail: rayt3@asme ... Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Model no. Base capacity(T/Hr) ... Mill output at raw coal moisture and at Coal HGI 100-110 31 . Fineness Requirement 32 . Duocast Roll .

获取价格

Mill Inerting and Pulverizer/Mill Explosion Mitigation

start-up, shutdown, mill trips and interruptions in raw coal feed. – Its well known the the risk of mill explosion is highest during these ... COMMON CAUSE OF MILL FIRES: COAL SPILLAGE UNDER THE BOWL. 500°F - 700°F . Air-to-Fuel Ratio by Design ~1.8:1 Air-to-Fuel Ratio . ... pulverizer or raw coal in the high temperature under bowl

获取价格

Reduced Unit Capacity

Feeder runback due to high mill or bowl differential. Feeders >100% are required. Excessive raw coal spillage. Excessive pulverizer vibration. Low Pulverizer airflow. Unit Availability and Capacity Factor. Pulverizer Motor Current. Motor amperage is an indication of how much “power” is being used and how much “work” is being done.

获取价格

bowl mill coal pulverizer - raw.githubusercontent

Get Solution Price Right Now! leave your message here, we'll send you an Email immediately. * *

获取价格

Pulverizer - Wikipedia

For example, a pulverizer mill is used to pulverize coal for combustion in the steam ... coal level in the mill offers a built-in capacity cushion of pulverized fuel to take care of short interruptions in the raw coal circuit. The mill is pressurized and the air-tightness is ensured by plenum chambers around the rotating trunnion filled with ...

获取价格

Coal Pulverizer - Pall

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise the majority of coal pulverizers currently in service at power generating facilities. In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive. ... Raw coal enters the top of the pulverizer through the raw coal feed ...

获取价格

Pulveriser Mill Performance Analysis Optimisation in Super

in the mining or coal processing operations. Fig.3 Mill fuel piping connections to furnace. II. COAL MILL SPECIFICATIONS PERFORMANCE ANALYSIS Typical Coal Pulveriser Mill Details in 660 MW Super-Critical [3] Unit is as given in table Table No. 1. Table.1 Coal mill Type Bowl Type Medium-speed Coal mill Number of Mills 6set/ boiler

获取价格

World-Proven Coal Pulverizer Technology Debuts in the U.S.

spring-loaded, MB type, vertical spindle mills, each gravimetric belt feeder, seal air fan, 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dual-fuel burners. When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffir.

获取价格

Optimum Operation and Maintenance of EL Pulverizers

Maintaining optimum sizing of raw coal to the pulverizer is mandatory in achieving capacity and fineness. Optimum raw coal feed size for EL pulverizers is ¾” to 1”. Raw coal feed should never exceed 1¼”, raw coal this size can plug throats and cause vibration. Raw coal that is too fine can plug the pulverizer or delivery components ...

获取价格

Coal Mill - an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003).In this model the coal mill is seen as one body with the mass m m.The following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is

获取价格

573 Raymond Bowl Mill - Wabash Power

(Three) Reconditioned Center Feed #573 C-E Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 26,500#/hr. on 55 grindibility coal pulverized to 70% minus 200 mesh. Mills are capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove coal but at a lower rating. Units are equipped with all internal related ...

获取价格